Electrical wires are essential components used to conduct electricity in various applications. They come in various types and materials suited for specific uses.

Electrical wires play a crucial role in transmitting electrical power and signals. These wires are made from conductive materials like copper and aluminum, ensuring efficient power transfer. Different types of electrical wires, such as solid, stranded, and coaxial, serve specific purposes in residential, commercial, and industrial settings.

Proper selection and installation of electrical wires are vital for safety and efficiency. Using the right gauge and type of wire can prevent electrical hazards and ensure optimal performance. Regular maintenance and inspection help in identifying wear and tear, which can prevent potential electrical failures and accidents.

History Of Electrical Wiring

The history of electrical wiring is a fascinating journey. It shows how we have harnessed electricity to power our lives. Let’s explore the key milestones in this journey.

Early Beginnings

Electrical wiring started in the late 19th century. Early wires were made from copper or aluminum. They were insulated with cloth, rubber, or paper. These materials were not always safe. Fires and electrical hazards were common.

Thomas Edison and Nikola Tesla played big roles in early electrical systems. Edison focused on direct current (DC) systems. Tesla championed alternating current (AC) systems. AC eventually became the standard due to its efficiency.

Advancements Over Time

Over time, electrical wiring improved greatly. New insulation materials were developed. These materials were safer and more durable. Plastic and synthetic rubber replaced older materials.

Grounding became a standard practice. Ground wires protect against electrical shocks. Circuit breakers and fuses were introduced. They prevent overloading and reduce fire risks.

Color coding of wires was established. This made it easier to identify different wires. For example, black wires are typically hot, white wires are neutral, and green or bare wires are ground.

| Year | Advancement |

|---|---|

| 1880s | Introduction of copper and aluminum wires |

| 1920s | Use of rubber insulation |

| 1950s | Introduction of plastic and synthetic rubber insulation |

| 1960s | Standardization of color coding |

| 1970s | Introduction of circuit breakers |

Today, modern electrical systems are highly advanced. Smart technology allows for better energy management. Safety standards are stricter than ever. This ensures homes and businesses are protected from electrical hazards.

Understanding the history of electrical wiring helps us appreciate the progress made. It also highlights the importance of continued innovation and safety in electrical systems.

Types Of Electrical Wires

Choosing the right electrical wire is important. Different wires suit different needs. This section explains the types of electrical wires.

Copper Wires

Copper wires are very common. They conduct electricity well. These wires are also durable. Copper wires resist heat.

Electricians use copper wires in homes and offices. They are safe and reliable. Copper wires are a bit expensive but worth it.

Aluminum Wires

Aluminum wires are lighter than copper wires. They are also cheaper. Many electricians use them for large projects.

Aluminum wires can carry electricity well. But they are less durable than copper. They may need special connectors to avoid corrosion.

Copper-clad Aluminum Wires

Copper-clad aluminum wires combine both metals. These wires have aluminum inside and copper outside. They are less expensive than pure copper wires.

These wires conduct electricity well. They are also lighter than copper wires. Many people use them to save money.

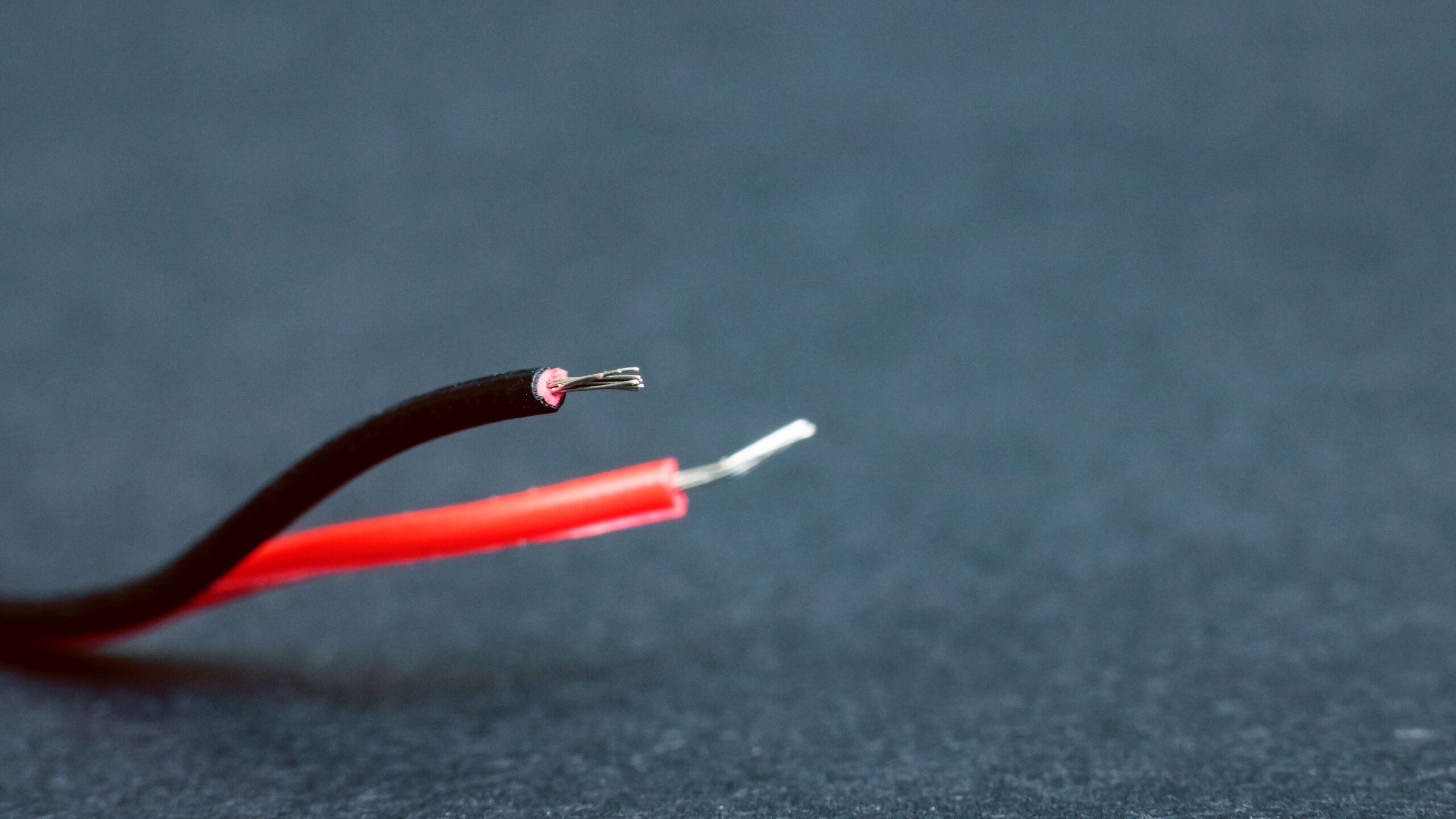

Solid Vs. Stranded Wires

Solid wires are made of one single piece of metal. They are stiff and less flexible. Solid wires are best for fixed positions.

Stranded wires have many small wires twisted together. They are flexible and can bend easily. Stranded wires are ideal for moving parts.

| Wire Type | Characteristics | Best Use |

|---|---|---|

| Copper | Durable, good conductor, heat-resistant | Homes, offices |

| Aluminum | Lightweight, less expensive | Large projects |

| Copper-Clad Aluminum | Combines copper and aluminum, cost-effective | Cost-saving projects |

| Solid | Stiff, less flexible | Fixed positions |

| Stranded | Flexible, easy to bend | Moving parts |

Wire Insulation Materials

Choosing the right insulation material is crucial for electrical wires. Insulation protects the wire from external factors and ensures safety. It also enhances the wire’s durability and performance.

Pvc Insulation

Polyvinyl Chloride (PVC) is one of the most popular wire insulation materials. PVC is highly durable and can withstand harsh conditions.

- Resistant to fire and chemicals

- Flexible and easy to work with

- Cost-effective and widely available

PVC insulation is ideal for home wiring and commercial applications. It offers excellent protection and longevity.

Rubber Insulation

Rubber insulation is known for its flexibility and resilience. It provides excellent thermal protection and is often used in high-temperature environments.

| Advantages | Details |

|---|---|

| Heat Resistance | Can withstand high temperatures |

| Durability | Highly durable and long-lasting |

| Flexibility | Easy to bend and shape |

Rubber insulation is perfect for industrial settings. It ensures that wires remain safe and functional under extreme conditions.

Thermoplastic Insulation

Thermoplastic insulation is a modern solution for wire insulation. It offers excellent electrical properties and is environmentally friendly.

- High resistance to abrasion and chemicals

- Lightweight and easy to install

- Recyclable and sustainable

Thermoplastic insulation is suitable for a variety of applications. It ensures safety and efficiency in both residential and commercial settings.

Wire Gauges And Sizes

Choosing the right wire gauge and size is crucial for electrical projects. It ensures safety and efficiency. Wire gauges and sizes determine the wire’s capacity to carry electrical currents. This blog post will delve into different sizing standards. We’ll cover the AWG Standard and Metric Sizing.

Awg Standard

American Wire Gauge (AWG) is a standard for wire diameters. It is widely used in North America. AWG sizes range from 0000 (4/0) to 40 AWG. The smaller the number, the larger the wire diameter. A 4/0 wire is much thicker than a 10 AWG wire.

AWG also affects the wire’s current-carrying capacity. Thicker wires can handle more current. For instance, 4/0 wire can carry up to 380 amps. In contrast, a 10 AWG wire can carry only 30 amps. The table below illustrates common AWG sizes and their diameters.

| AWG Size | Diameter (inches) | Current Capacity (amps) |

|---|---|---|

| 4/0 | 0.4600 | 380 |

| 2/0 | 0.3648 | 300 |

| 6 | 0.162 | 55 |

| 10 | 0.102 | 30 |

Metric Sizing

Metric sizing is another method for measuring wire diameters. It is commonly used outside North America. Metric sizes are measured in square millimeters (mm²). The larger the mm², the thicker the wire. A 16 mm² wire is thicker than a 1.5 mm² wire.

Metric sizes also impact the wire’s current-carrying capacity. For example, a 16 mm² wire can carry up to 76 amps. In contrast, a 1.5 mm² wire can carry only 20 amps. The table below shows common metric sizes and their current capacities.

| Metric Size (mm²) | Current Capacity (amps) |

|---|---|

| 16 mm² | 76 |

| 10 mm² | 52 |

| 4 mm² | 36 |

| 1.5 mm² | 20 |

Understanding wire gauges and sizes ensures the safe and efficient use of electrical wires. Use the right standard for your region and application. Whether using AWG or metric sizing, proper selection is key.

Common Uses Of Electrical Wires

Electrical wires play a crucial role in our daily lives. They power our homes, businesses, and industries. This section explores the common uses of electrical wires, highlighting their applications in residential, commercial, and industrial settings.

Residential Wiring

Electrical wires are essential for residential wiring. They provide power to lights, outlets, and appliances. Common types of wires used in homes include:

- Non-Metallic Sheathed Cable (NM): Used for indoor wiring.

- Underground Feeder (UF) Cable: Suitable for outdoor and underground use.

- Armored Cable (AC): Used in areas where extra protection is needed.

Each type has a specific use to ensure safety and efficiency. For instance, NM cable is often used in dry indoor locations, while UF cable is designed for wet or damp environments.

Commercial Wiring

In commercial settings, electrical wires power offices, retail stores, and other businesses. The wiring systems are more complex compared to residential wiring. Key types of commercial wiring include:

- THHN/THWN Wire: Used in conduits for general building wiring.

- MC Cable: Known for its flexibility and durability.

- Plenum Cable: Designed for spaces where air circulates for heating and cooling.

These wires must meet higher safety standards due to the higher power demands and the presence of multiple electrical devices.

Industrial Applications

Electrical wires in industrial settings handle heavy machinery and complex systems. They must withstand harsh conditions and high power loads. Common types of industrial wires include:

- Instrumentation Cable: Used for data and control signals in industrial processes.

- Tray Cable: Suitable for power and control applications.

- VFD Cable: Designed for variable frequency drives.

Industrial wires are built to be durable and reliable. They ensure continuous operation and safety in industrial environments.

Installation Of Electrical Wires

Installing electrical wires can seem like a daunting task. But with the right knowledge and tools, it becomes easier. This guide will walk you through the process step-by-step. Follow these instructions to ensure a safe and efficient installation.

Safety Precautions

Safety is the most important aspect when dealing with electrical wires. Always follow these precautions:

- Turn off the power at the main circuit breaker before starting.

- Wear protective gloves and goggles.

- Use insulated tools to avoid electric shocks.

- Ensure the work area is dry and well-lit.

- Double-check that the power is off using a voltage tester.

Tools Required

Having the right tools is essential for a successful installation. Here’s a list of what you need:

| Tool | Purpose |

|---|---|

| Wire Strippers | To remove insulation from the wires. |

| Voltage Tester | To check if the power is off. |

| Screwdrivers | For securing wires to outlets and switches. |

| Fish Tape | To guide wires through walls. |

| Electrical Tape | To insulate wire connections. |

| Cable Clips | To secure wires along walls. |

Step-by-step Guide

- Plan Your Wiring Route: Identify where you need to install the wires. Measure the distance and plan the route.

- Turn Off the Power: Go to your main circuit breaker and turn off the power supply.

- Prepare the Wires: Use wire strippers to remove about an inch of insulation from both ends of the wire.

- Run the Wires: Use fish tape to guide the wires through walls or conduits.

- Secure the Wires: Use cable clips to secure the wires along the planned route.

- Connect the Wires: Attach the wires to outlets, switches, or fixtures. Use screwdrivers for a secure connection.

- Insulate the Connections: Wrap electrical tape around wire connections to insulate them.

- Test the Installation: Turn the power back on. Use a voltage tester to ensure the installation is successful.

Following these steps ensures a safe and efficient installation of electrical wires. Always prioritize safety and use the right tools.

Maintaining Electrical Wiring

Maintaining electrical wiring is crucial for safety and efficiency. Proper care ensures the longevity of your electrical systems. It prevents potential hazards like fires or electrical shocks. This guide will help you understand the essential practices.

Inspection Practices

Regular inspections are vital for maintaining electrical wiring. Schedule inspections every six months. Use a checklist to keep track of your observations:

- Check for exposed wires.

- Look for any frayed or damaged insulation.

- Ensure all connections are secure.

- Test outlets and switches for functionality.

During inspections, use a flashlight to see dark areas. Wear protective gloves to avoid electric shocks. Document any issues you find for future reference.

Signs Of Wear And Tear

Identifying signs of wear and tear early can prevent serious problems. Here are some common indicators:

| Sign | Description |

|---|---|

| Flickering Lights | Lights that flicker may indicate loose connections. |

| Burning Smell | A burning smell often points to overheating wires. |

| Warm Outlets | Outlets that are warm to the touch could signal overload. |

| Tripped Circuit Breakers | Frequent tripping suggests an overloaded circuit. |

Address these signs promptly to avoid potential hazards. Ignoring them can lead to more significant issues down the line.

When To Replace Wiring

Knowing when to replace wiring is essential for safety. Here are some guidelines:

- If the wiring is over 30 years old, consider a replacement.

- Replace wiring after any significant electrical event, like a fire or flood.

- If you notice persistent issues, like frequent tripped breakers, consult a professional.

Replacing old or damaged wiring ensures your home stays safe. It also keeps your electrical system running efficiently.

Electrical Wire Color Codes

Electrical wires come in various colors. Each color has a specific meaning. Understanding these colors is crucial for safety and efficiency. This guide will help you decode the color codes used worldwide.

International Standards

Different countries use different color codes. Knowing these standards helps in global projects. Here are some common standards:

| Region | Live Wire | Neutral Wire | Earth Wire |

|---|---|---|---|

| USA | Black, Red | White | Green, Bare |

| UK | Brown | Blue | Green/Yellow |

| Europe | Brown | Blue | Green/Yellow |

Meaning Of Different Colors

Each color represents a different function. Here are the common meanings:

- Black: Used for live wires in the USA.

- Red: Another live wire color in the USA.

- White: Indicates a neutral wire in the USA.

- Brown: Live wire color in the UK and Europe.

- Blue: Neutral wire color in the UK and Europe.

- Green/Yellow: Represents earth or ground wire.

Understanding these color codes can prevent accidents. Always check the color before working with wires.

Safety Regulations For Electrical Wiring

Safety regulations for electrical wiring are crucial. They help prevent accidents and ensure safe electrical systems. Knowing these regulations can save lives. They also protect property from electrical hazards.

National Electrical Code (nec)

The National Electrical Code (NEC) is a standard for safe electrical design, installation, and inspection. The NEC is updated every three years to reflect new safety practices. Compliance with the NEC is mandatory in most areas of the United States.

The NEC covers many aspects of electrical wiring. This includes wire sizes, grounding methods, and circuit protection. It also includes installation guidelines and minimum safety requirements.

Compliance Standards

Compliance standards ensure electrical systems are safe and reliable. These standards are set by organizations like the National Fire Protection Association (NFPA). They also include guidelines from the Institute of Electrical and Electronics Engineers (IEEE).

Below are some important compliance standards:

- Wire Sizing: Correct wire size prevents overheating and fire.

- Grounding: Proper grounding prevents electric shock.

- Circuit Protection: Devices like fuses and breakers prevent overloads.

- Installation Practices: Proper installation prevents future issues.

Adhering to these standards is essential for safety. It also ensures the longevity of electrical systems. Always hire a certified electrician for any electrical work.

Future Trends In Electrical Wiring

The world of electrical wiring is evolving rapidly. With the rise of smart homes and IoT devices, new trends are emerging. These trends promise to make our lives easier and our homes more efficient.

Smart Wiring Systems

Smart wiring systems are at the forefront of modern electrical wiring. These systems integrate advanced technologies to enhance home automation. Smart wiring allows for seamless control of lighting, heating, and security systems.

These systems use advanced sensors and controllers. They can adjust lighting based on the time of day or occupancy. Homeowners can control devices remotely using smartphones or voice commands.

Here are some benefits of smart wiring systems:

- Energy Efficiency: Smart systems reduce energy consumption by optimizing device usage.

- Convenience: Remote access allows for easy control of home devices.

- Safety: Enhanced security features protect homes from intruders.

Smart wiring systems are paving the way for more connected and efficient homes.

Integration With Iot Devices

The integration with IoT devices is another significant trend. IoT, or the Internet of Things, connects everyday objects to the internet. This allows for better communication and control.

Electrical wiring systems now support IoT devices seamlessly. This means your refrigerator, washing machine, and even your coffee maker can be connected. You can control these devices using your smartphone or voice assistants like Alexa or Google Home.

Here are some advantages of integrating electrical wiring with IoT devices:

- Enhanced Control: Manage and monitor devices from anywhere in the world.

- Improved Efficiency: IoT devices optimize their operations for energy savings.

- Data Insights: Collect data on usage patterns to improve home efficiency.

With IoT integration, homes become smarter and more responsive to our needs.

Both smart wiring systems and IoT integration are transforming the landscape of electrical wiring. They offer exciting possibilities for the future of home automation.

Environmental Impact Of Electrical Wires

Electrical wires are essential in our modern lives. They power homes, offices, and industries. But, their production, use, and disposal can harm the environment. Understanding these impacts is vital for creating a sustainable future.

Recycling Initiatives

Recycling electrical wires helps reduce waste. Many metals in wires, like copper and aluminum, can be reused. This process saves raw materials and energy. It also reduces pollution from mining activities.

Companies and governments are promoting recycling programs. These initiatives encourage people to recycle old wires. Recycling centers are set up in many cities for this purpose.

Steps to recycle electrical wires:

- Collect old or unused wires.

- Separate the wires by material type.

- Take them to a designated recycling center.

By recycling wires, we can significantly cut down on environmental damage. It also promotes a circular economy where materials are reused.

Sustainable Practices

Adopting sustainable practices in wire production is crucial. Manufacturers are now looking for eco-friendly materials. They are also using energy-efficient methods in production.

Key sustainable practices include:

- Using recycled metals in wire production.

- Implementing energy-saving technologies in factories.

- Reducing the use of harmful chemicals in insulation.

These practices help reduce the carbon footprint of electrical wires. They also ensure less pollution and waste.

Consumers can also adopt sustainable habits. For instance, choosing wires with eco-friendly certifications. Properly disposing of old wires can also make a difference.

By embracing these sustainable practices, we can protect our planet. Every small action counts in creating a greener future.

Challenges In Electrical Wiring

Electrical wiring faces various challenges that can affect safety and efficiency. Understanding these challenges is crucial for maintaining a secure and functional electrical system.

Aging Infrastructure

Many buildings have old wiring systems. These systems may not meet current safety standards. Aging infrastructure can lead to frequent electrical issues.

Older wires can wear out. This increases the risk of electrical failures. Updating the wiring in old buildings is essential for safety.

Fire Hazards

Electrical wiring can pose fire hazards. Poorly installed or damaged wires can spark fires. This is especially dangerous in residential areas.

Regular inspection of electrical systems can reduce fire risks. Using high-quality materials and proper installation techniques is crucial.

Technical Obsolescence

Technology evolves quickly. Technical obsolescence in electrical wiring can make systems inefficient. Old systems may not support new devices and appliances.

Upgrading to modern wiring solutions can enhance performance. It ensures compatibility with current and future technologies.

Innovations In Wire Technology

Electrical wires are essential in modern life. Technology has advanced, making wires more efficient. Innovations in wire technology improve performance and safety. Let’s explore some exciting advancements in this field.

High-temperature Resistant Wires

High-temperature resistant wires can withstand extreme heat. These wires are used in harsh environments. They are vital in industries like aerospace and automotive.

These wires are made from special materials. They often use nickel alloys or ceramic compounds. These materials prevent the wires from melting or burning. This ensures the wires remain safe and functional.

Here are some key features:

- Durability: Withstand high temperatures without degradation.

- Safety: Reduce risk of fire hazards.

- Versatility: Used in various high-stress environments.

Superconducting Wires

Superconducting wires are another exciting innovation. They can conduct electricity without resistance. This means no energy is lost as heat. These wires are essential in applications requiring high efficiency.

Superconducting wires are used in MRI machines, particle accelerators, and power grids. They help to reduce energy consumption and improve performance.

Some benefits of superconducting wires include:

- Energy Efficiency: No energy loss during transmission.

- High Capacity: Can carry more current than traditional wires.

- Compact Design: Allows for smaller and lighter equipment.

Cost Considerations In Wiring Projects

Understanding the costs in wiring projects is crucial. Many factors influence the total expense. This section breaks down the main costs: materials, labor, and overall budgeting.

Material Costs

The type of wire you choose affects the cost. Copper wires are more expensive than aluminum wires. Each type has its own benefits and drawbacks. Here is a simple table for reference:

| Wire Type | Cost per Foot | Benefits |

|---|---|---|

| Copper | $0.50 | High conductivity, durable |

| Aluminum | $0.30 | Lightweight, cheaper |

Other materials include connectors, conduits, and switches. Each adds to the total cost. Bulk purchases can reduce costs. Always consider the quality to avoid future repairs.

Labor Costs

Labor is another major expense. Electricians charge based on their experience and the project’s complexity. The average rate ranges from $50 to $100 per hour. Complex projects may require more time. Here are some factors affecting labor costs:

- Project size: Larger projects take more time.

- Project complexity: Complex designs need skilled labor.

- Location: Urban areas often have higher labor rates.

Hiring licensed electricians ensures safety and compliance. It might cost more but saves money in the long run.

Total Project Budgeting

Creating a total project budget helps avoid surprises. Here are the steps to budget effectively:

- List all material costs.

- Estimate total labor hours needed.

- Include a contingency fund for unexpected expenses.

Use this formula to calculate the total budget:

Total Budget = (Material Costs + (Labor Rate x Hours)) + Contingency FundProper planning ensures the project stays within budget. Always review the budget and adjust as needed. This way, you manage costs effectively and avoid overspending.

Comparison Of Wired Vs. Wireless Systems

Choosing between wired and wireless systems can be tricky. Each has unique advantages. Understanding these can help you make the best decision.

Advantages Of Wired Systems

Wired systems are known for their reliability and stability. They face fewer interferences. This makes them ideal for critical applications.

- Consistent Connection: Wired systems offer a steady and uninterrupted connection.

- Security: They are less prone to hacking. This ensures better data protection.

- Speed: Wired connections typically provide faster data transfer rates.

These benefits make wired systems perfect for tasks that need high reliability and speed.

Advantages Of Wireless Systems

Wireless systems offer flexibility and convenience. They eliminate the need for physical cables.

- Ease of Installation: Wireless systems are easy to install and set up.

- Scalability: They can be easily expanded as your needs grow.

- Mobility: Users can move freely without being tethered to a spot.

These features make wireless systems suitable for dynamic environments and temporary setups.

Suitability For Different Applications

Choosing between wired and wireless systems depends on your specific needs.

| Application | Recommended System | Reason |

|---|---|---|

| Home Networking | Wireless | Flexibility and ease of installation |

| Office Networking | Wired | Reliability and speed |

| Industrial Settings | Wired | Stability and security |

| Temporary Events | Wireless | Quick setup and mobility |

Evaluate your needs carefully. This will guide you to the best choice for your situation.

The Role Of Electrical Wiring In Smart Homes

Smart homes are revolutionizing how we live, and electrical wiring plays a crucial role. It not only powers devices but also integrates with advanced technologies. Let’s explore how electrical wiring enhances smart homes.

Integration With Home Automation

Electrical wiring is the backbone of home automation. Smart lighting systems, automated thermostats, and security systems rely on robust wiring. Proper wiring ensures seamless communication between devices.

Consider a smart lighting system:

- Wiring connects lights to the central hub.

- Sensors detect motion and adjust lighting.

- Users control lights via mobile apps.

Proper electrical wiring enhances the efficiency of these systems. It ensures that your home automation devices work harmoniously.

Enhancing Energy Efficiency

Smart homes aim to reduce energy consumption. Optimized electrical wiring plays a pivotal role. It supports devices that monitor and manage energy usage.

Some key benefits include:

- Smart thermostats adjust heating and cooling based on occupancy.

- Energy monitoring systems provide real-time usage data.

- Automated lighting reduces electricity wastage.

Proper electrical wiring supports these devices effectively. It ensures that they operate without interruptions, maximizing energy efficiency.

Global Market Trends In Electrical Wiring

The global market for electrical wiring is rapidly evolving. Technological advancements and increasing urbanization drive this growth. Understanding the trends helps in making informed decisions. Here, we explore the demand forecast and key players in the industry.

Demand Forecast

The demand for electrical wires is expected to surge. New infrastructure projects and smart home technologies fuel this growth. Electric vehicles (EVs) are another major driver. They require specialized wiring systems for efficient operation.

A table below shows the projected growth in key regions:

| Region | 2023 (in million USD) | 2025 (in million USD) | Growth Rate (%) |

|---|---|---|---|

| North America | 15,000 | 18,500 | 23.3 |

| Europe | 12,000 | 14,600 | 21.7 |

| Asia-Pacific | 20,000 | 28,000 | 40.0 |

Asia-Pacific leads the growth due to rapid industrialization and urbanization. North America and Europe also show strong growth driven by technological innovations.

Key Players In The Industry

Several companies dominate the electrical wiring market. These key players include:

- Prysmian Group: Known for high-quality cables and systems.

- Nexans: A leader in advanced cabling solutions.

- General Cable: Offers a wide range of wire and cable products.

- Southwire: Specializes in electrical wires and cables.

- Sumitomo Electric Industries: A major player in automotive wiring.

These companies invest heavily in research and development. They aim to produce more efficient and durable wiring solutions. Innovations in materials and manufacturing techniques are their primary focus areas.

The global market trends in electrical wiring are clear. Demand is growing, and key players are investing in innovation. Staying updated on these trends is crucial for anyone involved in the industry.

Importance Of Proper Grounding In Electrical Wiring

Proper grounding in electrical wiring is vital for safety and functionality. It ensures the electrical system operates correctly and protects people and devices.

Preventing Electric Shocks

Electric shocks can be dangerous and even deadly. Proper grounding helps to prevent these shocks. Grounding provides a safe path for electricity to flow back to the ground. This way, if there’s a fault, the electricity will not pass through people.

Grounding also helps devices work correctly. It prevents the buildup of static electricity, which can cause shocks. This is important for both homes and workplaces.

| Benefit | Description |

|---|---|

| Prevents Electric Shocks | Provides a safe path for electricity to flow back to the ground. |

| Protects Devices | Prevents static electricity buildup, ensuring device functionality. |

Protecting Against Overloads

Proper grounding is crucial in protecting against electrical overloads. It ensures excess electricity is safely directed away. Overloads can happen when too many devices are plugged in. Grounding prevents damage to the electrical system.

Grounding also protects from lightning strikes. If lightning hits a building, grounding directs the electricity safely into the earth. This prevents fires and damage to electrical appliances.

- Protects from electrical overloads

- Saves devices from damage

- Prevents fires from lightning strikes

The Evolution Of Wiring Standards

Electrical wiring standards have changed greatly over time. These changes ensure safety and efficiency in our homes and workplaces. Let’s explore how wiring standards have evolved, focusing on safety codes and international harmonization efforts.

Safety Codes

Safety codes are rules that ensure electrical systems are safe. They protect people and property from electrical hazards.

- In the past, safety codes were not strict. Many homes had unsafe wiring.

- Modern safety codes are very strict. They include rules about wire size, insulation, and grounding.

- Electricians must follow these codes to prevent fires and electric shocks.

Building inspectors check electrical work to ensure it meets safety codes. This helps keep everyone safe.

International Harmonization Efforts

International harmonization efforts aim to make wiring standards the same around the world. This helps ensure that electrical systems are safe everywhere.

- Different countries have different wiring standards.

- These differences can cause problems when installing electrical systems.

- Harmonization efforts try to create one global standard. This makes it easier for electricians to work in different countries.

Organizations like the International Electrotechnical Commission (IEC) work on these efforts. They create standards that countries can follow.

Harmonized standards make it easier to trade electrical goods. They also ensure that these goods are safe to use.

| Country | Wiring Standard | Harmonized Standard |

|---|---|---|

| United States | National Electrical Code (NEC) | IEC 60364 |

| United Kingdom | BS 7671 | IEC 60364 |

| Germany | DIN VDE 0100 | IEC 60364 |

Harmonized standards help ensure that electrical systems are safe and reliable worldwide. They make our lives easier and safer.

The Impact Of Electrical Wiring On Building Design

The design of a building isn’t just about walls and windows. Electrical wiring plays a crucial role in shaping modern architecture. It’s essential for safety, functionality, and aesthetics. As technology advances, the need for strategic electrical planning grows. Let’s explore how electrical wiring impacts building design.

Integration Into Architectural Plans

Architects must consider electrical wiring during the initial design phase. This ensures a seamless integration of functionality and aesthetics. Here are some key points:

- Ensure adequate power distribution.

- Plan for future expansions and upgrades.

- Maintain accessibility for repairs and maintenance.

Electrical plans must align with architectural blueprints. It helps in avoiding costly modifications later. A well-integrated electrical plan ensures efficiency and safety. This is critical for both residential and commercial buildings.

Aesthetics Vs. Functionality

Balancing aesthetics and functionality is crucial in modern building design. Electrical wiring should not compromise the look of a space. Yet, it must meet all functional requirements. Here are some considerations:

| Aspect | Considerations |

|---|---|

| Concealment | Use conduits, raceways, and other methods to hide wires. |

| Accessibility | Ensure easy access for maintenance without disrupting aesthetics. |

| Technology | Incorporate smart home systems and energy-efficient solutions. |

Walls, floors, and ceilings often house electrical components. Concealed wiring keeps spaces clean and modern. Yet, it’s vital to maintain easy access for troubleshooting. The right balance creates functional and beautiful spaces.

Frequently Asked Questions

What Are The Three Types Of Electrical Wires?

The three types of electrical wires are: 1. **Live (or hot) wires** – carry current from the power source to the load. 2. **Neutral wires** – return the current from the load back to the power source. 3. **Ground wires** – provide a safe path for electricity in case of a fault.

What Are The Colors Of The Electrical Wires?

Electrical wire colors include black, red, and blue for hot wires, white for neutral, and green or bare for ground.

What Wires Are Used In Electrical?

Common wires in electrical work include copper, aluminum, and fiber optic cables. Copper wires are highly conductive and durable. Aluminum wires are lightweight and cost-effective. Fiber optic cables are used for high-speed data transmission.

What Type Of Wire Is Used For Outlets?

Use 12-gauge or 14-gauge copper wire for outlets. Choose 12-gauge for 20-amp circuits and 14-gauge for 15-amp circuits.

Conclusion

Choosing the right electrical wires ensures safety and efficiency in your projects. Always consider the wire type and specifications. Properly installed wires can prevent hazards and costly repairs. Stay informed and consult professionals for the best results. Your electrical system’s performance depends on the quality and suitability of the wires used.