Electricians grease, also known as dielectric grease, prevents corrosion and improves electrical connections. It’s essential for maintaining electrical systems.

Electricians grease is a silicone-based compound used to protect electrical connections. This grease prevents corrosion, moisture, and dirt from compromising electrical contacts. It enhances the efficiency and longevity of electrical systems. Electricians apply it to connectors, battery terminals, and other electrical components.

Its non-conductive nature ensures no interference with electrical signals. Using electricians grease is crucial for both residential and commercial electrical maintenance. It also aids in reducing wear and tear on electrical parts. This simple, yet effective product is a staple in every electrician’s toolkit. It ensures reliable and safe electrical connections, making it indispensable for electrical work.

The Role Of Electrician’s Grease

Electrician’s grease is a vital tool for professionals. It ensures electrical connections remain smooth and durable. This specialized grease prevents many common issues. Below, we explore its key roles.

Ensuring Smooth Connections

Electrician’s grease ensures connections are smooth and efficient. It lubricates contact points to reduce friction. Friction can cause wear and tear. With this grease, connections last longer and work better.

Additionally, it helps in the easy assembly and disassembly of parts. This makes maintenance tasks simpler and quicker. Professionals save time and effort using electrician’s grease.

Preventing Corrosion And Oxidation

Corrosion and oxidation are major problems for electrical connections. Electrician’s grease acts as a protective barrier. This barrier stops moisture and air from causing damage. By preventing corrosion, it extends the life of electrical components.

Below is a table showing the benefits of using electrician’s grease:

| Benefit | Description |

|---|---|

| Prevents Corrosion | Stops moisture from causing rust |

| Prevents Oxidation | Protects against air exposure |

| Ensures Smooth Connections | Reduces friction and wear |

| Easy Maintenance | Simplifies assembly and disassembly |

Using electrician’s grease is a smart choice for professionals. It ensures reliable and long-lasting electrical connections.

Types Of Grease Used In Electrical Work

Electricians use different types of grease for various electrical tasks. These greases help protect and maintain electrical systems. Each type of grease has unique properties and applications.

Dielectric Grease Varieties

Dielectric grease is a non-conductive grease. It protects electrical connections from moisture and corrosion. This type of grease is essential for keeping connections clean and dry.

- Silicone-based Dielectric Grease: This is the most common type. It resists high temperatures and provides excellent insulation.

- Non-silicone Dielectric Grease: This is used where silicone is not suitable. It works well in sensitive environments.

Conductive Grease Applications

Conductive grease is used where conductivity is needed. It improves electrical connections and reduces resistance. This grease is vital for ensuring good contact between surfaces.

- Silver Conductive Grease: Contains silver particles. It provides excellent conductivity and is used in critical applications.

- Graphite Conductive Grease: Contains graphite particles. It is less expensive and used in less critical applications.

| Type of Grease | Properties | Applications |

|---|---|---|

| Silicone-based Dielectric Grease | High temperature resistance, excellent insulation | General electrical connections |

| Non-silicone Dielectric Grease | Suitable for sensitive environments | Special electrical systems |

| Silver Conductive Grease | High conductivity, critical applications | Important electrical connections |

| Graphite Conductive Grease | Moderate conductivity, cost-effective | Less critical connections |

Key Properties Of Electrician’s Grease

Electrician’s grease is crucial for electrical maintenance. It ensures smooth connections and prevents corrosion. Understanding its key properties helps in choosing the right product.

Viscosity And Consistency

The viscosity of electrician’s grease defines its flow. High viscosity means the grease is thick. Low viscosity means it’s thin. Consistency relates to how the grease holds together. A good electrician’s grease should balance both. It should be thick enough to stay in place. But it should flow easily when applied.

| Viscosity | Consistency |

|---|---|

| Thick | Stays in place |

| Thin | Flows easily |

Electrical Insulation Characteristics

Electrician’s grease must have excellent electrical insulation properties. This ensures no electrical current flows through the grease. Proper insulation prevents short circuits. It also protects against electrical shocks.

- Prevents electrical current flow

- Reduces short circuit risks

- Protects against shocks

These properties make electrician’s grease indispensable. It ensures safety and efficiency in electrical work.

Applying Grease: Best Practices

Applying electrician’s grease correctly ensures optimal performance and longevity of electrical contacts. Following best practices helps in achieving efficient results. Below are key steps and techniques to consider.

Preparation Of Contact Surfaces

Proper preparation of contact surfaces is crucial. Dirty or corroded surfaces can hinder the effectiveness of the grease. Follow these steps:

- Clean the surfaces with a suitable cleaner.

- Use a soft brush to remove debris.

- Ensure the surfaces are dry before applying grease.

Cleaning ensures better grease adhesion and performance. Dry surfaces prevent unwanted reactions.

Techniques For Effective Application

Applying grease effectively requires attention to detail. Follow these techniques for the best results:

- Use a small amount of grease.

- Apply evenly using a brush or applicator.

- Ensure a thin layer covers the entire surface.

Excess grease can attract dust. A thin layer ensures efficient performance without attracting debris.

| Step | Action | Purpose |

|---|---|---|

| 1 | Clean | Remove debris |

| 2 | Dry | Prevent reactions |

| 3 | Apply | Ensure even coverage |

Following these steps ensures optimal performance of electrical contacts. Proper application extends the lifespan and reliability of your electrical components.

Safety Measures When Using Electrical Grease

Using electrical grease can make your electrical work safer. But, it is important to follow safety measures. This guide will help you stay safe.

Personal Protective Equipment

Always wear proper Personal Protective Equipment (PPE).

- Gloves: Protect your hands from chemicals.

- Safety glasses: Keep your eyes safe from splashes.

- Protective clothing: Avoid skin contact with the grease.

Proper Storage And Disposal

Store and dispose of electrical grease correctly.

| Action | Details |

|---|---|

| Storage | Keep in a cool, dry place. Away from heat and flame. |

| Disposal | Follow local regulations. Use designated disposal sites. |

Follow these safety tips to use electrical grease safely. Stay protected and handle materials properly.

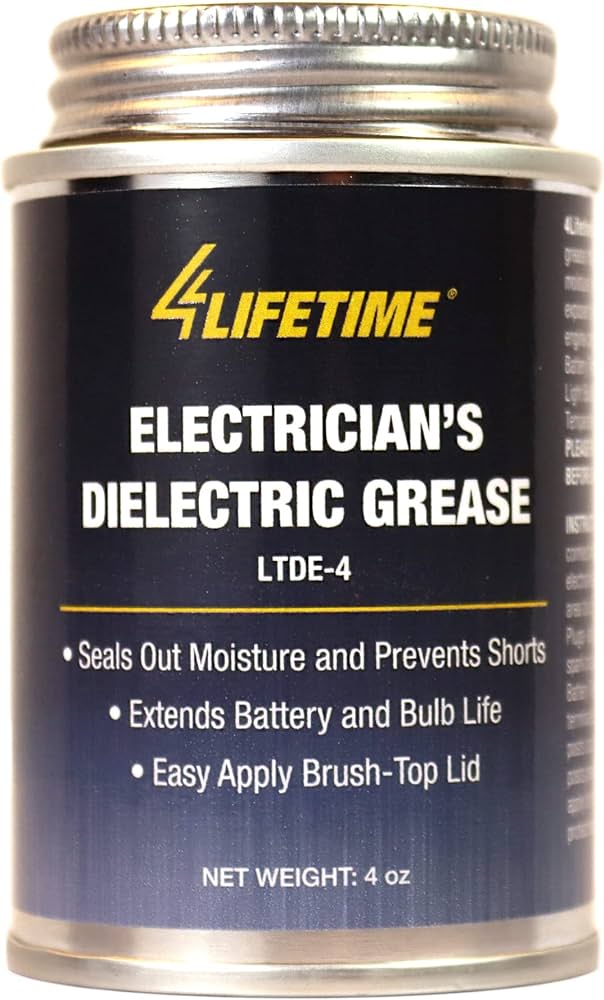

Credit: www.amazon.com

Common Mistakes To Avoid

Using electrician’s grease is crucial for electrical connections. Many people make mistakes that can lead to problems. Here are the common mistakes to avoid.

Overapplication And Its Consequences

Overapplying electrician’s grease is a common mistake. Too much grease can cause issues. It can attract dust and debris. This will lead to poor connections.

Excess grease may also squeeze out. This can reach unwanted areas. It may cause short circuits. Always apply a thin, even layer. Less is more in this case.

Choosing The Wrong Grease Type

Choosing the wrong type of grease can be a big problem. There are different types of grease for different jobs.

- Dielectric grease is for insulating and protecting connections.

- Conductive grease enhances electrical conductivity.

If you use the wrong type, it can harm the connection. Always check the label. Ensure you have the right grease for the job.

The Impact Of Environment On Grease Performance

Electricians grease is essential for maintaining electrical connections. The environment can affect its performance. Understanding these impacts helps in choosing the right grease. Below, we explore different environmental factors.

Temperature Extremes

High and low temperatures impact grease significantly. In extreme heat, grease can thin out. This reduces its ability to lubricate effectively. In cold conditions, grease can thicken. This may cause it to lose its lubricating properties.

| Temperature | Effect on Grease |

|---|---|

| High | Grease thins out |

| Low | Grease thickens |

Moisture And Humidity Effects

Moisture can degrade the effectiveness of grease. Water can mix with grease, leading to poor lubrication. This can cause corrosion in electrical connections. High humidity can also be problematic. It can lead to condensation inside connections.

- Water mixing with grease

- Corrosion in electrical connections

- Condensation in high humidity

Using waterproof grease can help. It repels moisture and maintains its properties. This ensures long-lasting protection for electrical connections.

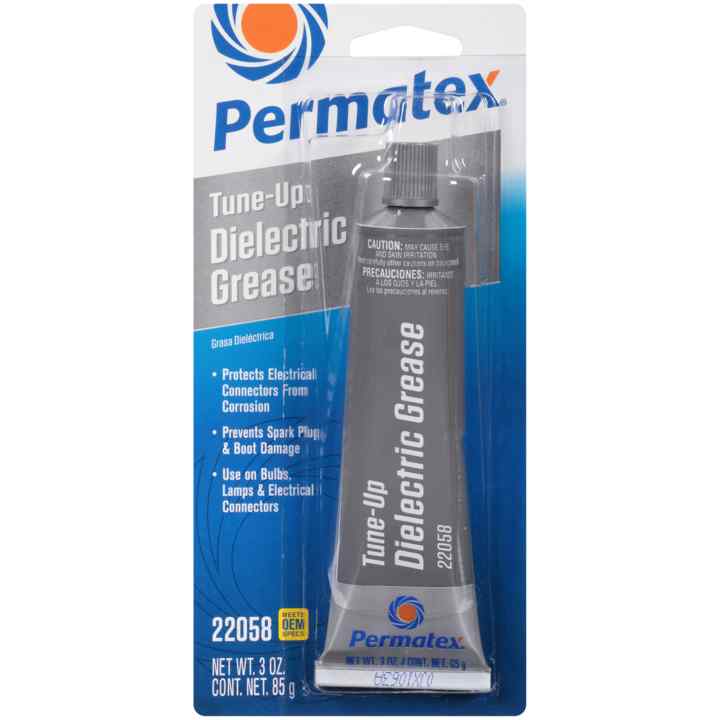

Credit: www.permatex.com

Case Studies: Electrician’s Grease In Action

Electrician’s grease is a versatile tool for professionals. It enhances performance and ensures safety. Let’s look at its practical applications in real-life scenarios.

Residential Wiring Success Stories

Electrician’s grease has transformed residential wiring projects. It ensures smooth and safe connections. Here are some success stories:

- Home Renovation: During a home renovation, an electrician used grease on all wiring connections. This reduced wear and tear, ensuring long-lasting performance.

- New Installations: In new homes, electricians applied grease to prevent corrosion. This improved reliability and reduced maintenance costs.

Industrial Applications And Results

In industrial settings, electrician’s grease is a game-changer. It protects equipment and enhances efficiency. Here are some notable case studies:

| Industry | Application | Results |

|---|---|---|

| Manufacturing | Used on heavy machinery wiring | Reduced downtime by 30% |

| Construction | Applied to electrical connections | Increased safety and reliability |

Electrician’s grease makes a significant difference. It ensures smoother operations and longer-lasting systems.

Credit: www.homedepot.com

Frequently Asked Questions

What Kind Of Grease Do You Use For Electrical Connections?

Use dielectric grease for electrical connections. It prevents corrosion, moisture, and enhances conductivity. Ideal for automotive and marine applications.

What Is The Best Grease For Electrical Conductivity?

The best grease for electrical conductivity is a conductive grease, such as carbon or silver-filled types. These greases enhance electrical connections and prevent corrosion.

What’s The Difference Between Electrical Grease And Regular Grease?

Electrical grease insulates and protects electrical connections from moisture and corrosion. Regular grease lubricates mechanical parts, reducing friction.

What Can Be Used As Conductive Grease?

Conductive grease options include silicone-based, carbon-based, and silver-filled greases. These enhance electrical connections and prevent corrosion.

Conclusion

Electricians grease is essential for ensuring safe and efficient electrical connections. It prevents corrosion and enhances conductivity. By using electricians grease, you can prolong the lifespan of electrical components. Make sure to choose high-quality grease for optimal performance. Keep your electrical systems running smoothly with this simple yet effective solution.