Arc flash is a dangerous electrical explosion caused by a short circuit. It can result in severe injuries or fatalities.

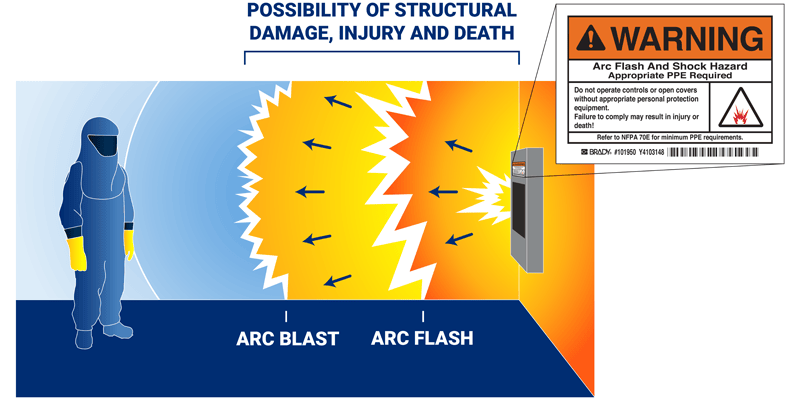

Arc flash occurs when an electric current veers off its intended path, traveling through the air and creating a fiery explosion. This phenomenon can cause severe burns, hearing loss, and even death. Workers in electrical environments face the highest risk.

Safety measures, including proper training, protective gear, and regular equipment maintenance, are crucial to prevent arc flash incidents. Understanding the hazards and implementing stringent safety protocols can significantly reduce the risk. Employers must prioritize safety to protect their workforce and maintain a safe working environment. Effective arc flash prevention not only safeguards lives but also ensures operational continuity.

What Is Arc Flash

Arc Flash is a dangerous electrical phenomenon that can occur when there is a rapid release of energy due to an electrical fault. This release of energy results in an explosion of light and heat, which can cause severe injuries, fires, and even fatalities. Understanding what Arc Flash is and how it can be prevented is crucial in maintaining a safe working environment.

Definition

Arc Flash is a sudden and violent electrical explosion that occurs due to a fault in an electrical circuit. It is characterized by intense heat, light, and sound, which can cause serious injuries to individuals in the vicinity. The heat produced during an Arc Flash can reach temperatures hotter than the surface of the sun, leading to burns and thermal injuries. The light emitted during an Arc Flash can be blinding, further increasing the risk of accidents.

Causes

Arc Flash can be caused by various factors, including:

- Faulty equipment or improper maintenance

- Accidental contact with electrical systems

- Dust, debris, or corrosion on electrical components

- Unsafe work practices or human error

These causes can lead to a buildup of electrical energy, creating conditions ripe for an Arc Flash event. It is essential for individuals working with electrical systems to be aware of these causes and take necessary precautions to prevent Arc Flash incidents.

Credit: www.healthandsafetyinternational.com

Arc Flash Hazards

Arc Flash is a dangerous electrical event that can result in severe injuries or even death. Arc Flash Hazards are critical to understand for anyone working with or around electrical systems. This blog post will explore the risks and potential injuries associated with Arc Flash.

Risk Assessment

Conducting a risk assessment for Arc Flash is essential in identifying potential hazards and implementing safety measures. A thorough risk assessment involves several steps:

- Identify Electrical Equipment: Determine which equipment poses a risk of Arc Flash.

- Analyze Work Tasks: Evaluate tasks that involve interaction with electrical systems.

- Assess Potential Exposure: Consider the likelihood of an Arc Flash occurring during specific tasks.

- Determine Severity: Estimate the potential severity of an Arc Flash incident.

A detailed risk assessment should include the following components:

| Component | Description |

|---|---|

| Equipment Identification | List all electrical equipment that could be a source of Arc Flash. |

| Task Analysis | Evaluate tasks involving the equipment and their risk levels. |

| Exposure Assessment | Assess the probability of Arc Flash exposure during tasks. |

| Severity Determination | Estimate the potential impact and severity of an Arc Flash event. |

By following these steps, businesses can create a safer work environment and minimize the risk of Arc Flash incidents.

Potential Injuries

Standards And Regulations

Arc flash incidents can be deadly, causing severe injuries and even fatalities. Understanding the standards and regulations surrounding arc flash is vital for ensuring workplace safety. This section dives into the key standards and regulations that govern arc flash safety, emphasizing the most critical guidelines.

Nfpa 70e

The NFPA 70E standard is crucial for electrical safety in the workplace. It provides guidelines to help prevent arc flash incidents. Key elements of NFPA 70E include:

- Risk Assessment Procedures: Identifying hazards and assessing risks.

- Arc Flash Boundary: Establishing safe distances from potential arc flash sources.

- Personal Protective Equipment (PPE): Mandating proper gear to minimize injuries.

- Training Requirements: Ensuring employees are well-trained in electrical safety.

NFPA 70E outlines specific risk assessment procedures to identify and mitigate potential hazards. These procedures help in understanding the severity of arc flash risks and implementing control measures. The standard also defines the Arc Flash Boundary, which is the distance within which a person is at risk of injury from an arc flash. Proper establishment of this boundary is crucial for maintaining a safe working environment.

Personal Protective Equipment (PPE) is another vital aspect of NFPA 70E. The standard specifies the types of PPE required based on the level of risk. This ensures workers are adequately protected against potential arc flash hazards. Lastly, training requirements are emphasized, ensuring that all employees receive the necessary training to handle electrical systems safely.

Osha Guidelines

The Occupational Safety and Health Administration (OSHA) also plays a significant role in regulating electrical safety. OSHA guidelines mandate several key practices to protect workers from arc flash incidents. Key OSHA guidelines include:

- Electrical Safety Program: Implementing a comprehensive safety program.

- Hazard Analysis: Conducting thorough hazard assessments.

- Control Measures: Establishing controls to mitigate risks.

- Employee Training: Ensuring proper training and awareness.

OSHA requires employers to implement a comprehensive Electrical Safety Program. This program should outline all procedures and practices for maintaining electrical safety in the workplace. A critical component of this program is conducting hazard analysis to identify potential arc flash risks. Once hazards are identified, appropriate control measures must be established to mitigate these risks.

OSHA also emphasizes the importance of employee training. Workers must be trained to understand the hazards associated with arc flash and the proper safety protocols. This training is essential for fostering a culture of safety and ensuring that employees are well-prepared to handle electrical systems safely.

Preventive Measures

Arc Flash incidents can cause severe injuries or even death. Preventive measures are crucial to ensure safety in environments where Arc Flash risks are present. Implementing these measures can save lives and prevent property damage. Below are some key preventive measures.

Personal Protective Equipment

Wearing the right Personal Protective Equipment (PPE) is essential to reduce the risk of injury from Arc Flashes. Different types of PPE offer varying levels of protection. Selecting the appropriate gear based on the hazard level is crucial.

Here is a list of important PPE items:

- Arc-rated clothing: These garments are designed to resist the intense heat and energy of an Arc Flash.

- Face shields: Protects the face from burns and flying debris.

- Insulated gloves: Essential for protecting hands from electrical shocks and burns.

- Safety boots: Provide foot protection with insulating soles to prevent electric shock.

- Hearing protection: Reduces the risk of ear damage from the loud noise of an Arc Flash.

Wearing the right PPE can make a significant difference in preventing severe injuries. Always ensure that PPE is in good condition and free from damage. Regular inspections and maintenance of PPE are crucial for maximum effectiveness.

Maintenance Practices

Proper maintenance practices are vital for preventing Arc Flash incidents. Regular inspections and timely repairs can greatly reduce risks.

Here are some key maintenance practices:

- Regular equipment inspections: Check electrical equipment frequently to identify wear and tear.

- Timely repairs: Fix any identified issues immediately to prevent escalation.

- Cleaning: Keep electrical panels and equipment clean to prevent dust and debris buildup.

- Up-to-date documentation: Maintain accurate records of all maintenance activities.

- Training: Ensure that all personnel are trained in proper maintenance procedures.

Here is a table summarizing the key maintenance activities and their importance:

| Maintenance Activity | Importance |

|---|---|

| Regular Inspections | Identifies potential issues early |

| Timely Repairs | Prevents escalation of problems |

| Cleaning | Prevents dust and debris buildup |

| Up-to-date Documentation | Ensures accurate maintenance records |

| Training | Ensures proper maintenance procedures |

Implementing these maintenance practices helps in mitigating the risk of Arc Flash incidents. Regular checks and timely repairs ensure that equipment remains safe and functional.

Arc Flash Studies

Arc Flash Studies are crucial for ensuring electrical safety in industrial settings. These studies analyze the potential hazards associated with arc flashes, helping to prevent accidents and ensure the safety of personnel. Arc Flash Studies involve detailed assessments, including Short-Circuit Analysis and Coordination Study, which are essential for understanding and mitigating risks.

Short-circuit Analysis

A Short-Circuit Analysis is a key component of Arc Flash Studies. It identifies the potential fault currents that can occur in an electrical system. This analysis helps in determining the interrupting capacity of circuit breakers and fuses.

Key elements of a Short-Circuit Analysis include:

- Fault Current Calculation: Determines the maximum current that can flow during a fault.

- System Modeling: Uses software tools to create a detailed model of the electrical network.

- Equipment Rating: Ensures that all equipment can handle the calculated fault currents.

The analysis process involves the following steps:

- Gathering data on the electrical system, such as one-line diagrams and equipment ratings.

- Using specialized software to simulate fault conditions.

- Reviewing and verifying the results to ensure accuracy.

By performing a Short-Circuit Analysis, engineers can identify weaknesses in the system and recommend upgrades to improve safety and reliability.

Coordination Study

A Coordination Study is another critical aspect of Arc Flash Studies. It ensures that protective devices operate in a coordinated manner during faults. This study minimizes system downtime and prevents equipment damage.

Key elements of a Coordination Study include:

- Time-Current Curves: Plots the operating times of protective devices against fault currents.

- Device Settings: Adjusts settings to ensure proper coordination between devices.

- Selectivity Analysis: Ensures that only the faulty section of the system is isolated.

The study process involves the following steps:

- Collecting data on protective devices, such as relays, circuit breakers, and fuses.

- Analyzing the time-current characteristics of each device.

- Adjusting device settings to achieve optimal coordination.

Performing a Coordination Study helps in maintaining system stability, reducing the risk of widespread outages, and ensuring the safety of personnel.

Incident Response

Arc Flash incidents can be extremely dangerous, causing severe injuries or even fatalities. Knowing how to respond swiftly and effectively is crucial. This section will guide you through the essential steps of incident response, focusing on emergency procedures and first aid.

Emergency Procedures

Immediate action is essential during an Arc Flash incident. Quick and decisive measures can save lives and minimize injuries. Follow these steps:

- Shut off the power: The first step is to turn off the power source to prevent further electrical hazards.

- Alert emergency services: Dial emergency numbers and provide details about the incident.

- Evacuate the area: Ensure everyone is at a safe distance from the incident site.

- Use safety equipment: Wear protective gear if you need to approach the affected area.

- Isolate the area: Use barriers or signs to keep unauthorized personnel away.

Having a well-defined emergency plan is crucial. Everyone should know their role and the location of safety equipment. Regular drills can help prepare for real-life scenarios.

| Action | Details |

|---|---|

| Shut off power | Locate and turn off the main power source |

| Alert emergency services | Call 911 or local emergency number |

| Evacuate area | Move everyone to a safe distance |

| Use safety equipment | Wear protective gear like gloves and masks |

| Isolate the area | Set up barriers or signs |

First Aid

First aid is critical to treat injuries from an Arc Flash. Follow these steps to provide immediate care:

- Assess the victim: Check for responsiveness and breathing. If not breathing, start CPR.

- Treat burns: Cool burns with cold water but avoid ice. Cover with a clean cloth.

- Stop bleeding: Apply pressure with a clean cloth to any bleeding wounds.

- Monitor vital signs: Keep track of the victim’s breathing and pulse.

- Prevent shock: Keep the victim warm and elevate their legs if possible.

- Stay with the victim: Do not leave the injured person alone until help arrives.

First aid kits should be easily accessible and well-stocked. Basic training in first aid can make a huge difference in emergency situations.

| Action | Details |

|---|---|

| Assess the victim | Check responsiveness and start CPR if needed |

| Treat burns | Use cold water, avoid ice, cover with a clean cloth |

| Stop bleeding | Apply pressure with a clean cloth |

| Monitor vital signs | Check breathing and pulse regularly |

| Prevent shock | Keep warm, elevate legs |

| Stay with the victim | Do not leave until emergency help arrives |

Training And Awareness

Arc flash events pose significant dangers in industrial settings. Training and awareness are crucial in ensuring safety. Employees must understand the risks and know how to act to prevent accidents.

Employee Training Programs

Employee training programs are essential in mitigating arc flash hazards. These programs educate workers about the dangers and provide practical knowledge to handle electrical systems safely.

Training programs often include:

- Classroom Sessions: Theoretical knowledge about arc flash, its causes, and prevention.

- Hands-on Training: Practical exercises on using protective gear and handling equipment.

- Online Modules: Accessible training materials and quizzes to reinforce learning.

In addition to these methods, companies can provide customized training tailored to specific job roles. This ensures every employee understands their responsibilities.

Here is a table summarizing key components of an effective employee training program:

| Component | Description |

|---|---|

| Theoretical Knowledge | Understanding arc flash risks and safety protocols. |

| Practical Exercises | Hands-on practice with safety equipment and procedures. |

| Online Learning | Interactive modules and assessments. |

| Role-Specific Training | Custom sessions based on job duties. |

Safety Drills

Safety drills are a key part of maintaining a safe work environment. Regular drills help employees practice their responses to arc flash incidents. This preparedness is vital in minimizing injuries.

Effective safety drills should include:

- Scenario-Based Drills: Simulate real-life arc flash incidents to test responses.

- Use of Safety Equipment: Practice using PPE and other safety gear.

- Emergency Procedures: Ensure everyone knows evacuation routes and first-aid steps.

Safety drills should be conducted periodically to keep skills sharp. Employees should also receive feedback after each drill to improve their performance.

Tracking the effectiveness of safety drills can be done through evaluation forms and debriefing sessions. Here is a brief outline of a safety drill evaluation form:

| Evaluation Criteria | Rating (1-5) | Comments |

|---|---|---|

| Response Time | ||

| Proper Use of Equipment | ||

| Adherence to Procedures | ||

| Overall Preparedness |

Regular and well-structured safety drills ensure employees are always prepared for any arc flash incident.

Credit: www.bradyid.com

Future Trends

Arc Flash incidents are dangerous electrical events that can cause severe injuries and damage. Understanding future trends in Arc Flash safety is crucial for industries to protect workers and infrastructure. This blog explores the latest advancements and innovations shaping the future of Arc Flash prevention.

Technological Advances

Modern technology is revolutionizing Arc Flash safety. New tools and systems are making workplaces safer. Here are some key advancements:

- Wearable Technology: Smart clothing equipped with sensors can monitor electrical exposure. These wearables alert workers to potential Arc Flash hazards instantly.

- Advanced PPE: Personal protective equipment is becoming more advanced. Innovations like fire-resistant fabrics and ergonomic designs improve safety and comfort.

- Predictive Maintenance: IoT devices and AI algorithms predict equipment failures before they happen. This reduces the risk of Arc Flash incidents.

Check out the table below for a quick summary of technological advances:

| Technology | Benefit |

|---|---|

| Wearable Sensors | Immediate hazard alerts |

| Advanced PPE | Better protection and comfort |

| Predictive Maintenance | Reduced equipment failures |

Industry Innovations

Industries are adopting new practices to minimize Arc Flash risks. Here are some notable innovations:

- Enhanced Training Programs: Virtual reality (VR) simulations are now used for training. Workers can experience realistic Arc Flash scenarios safely.

- Improved Safety Standards: Regulatory bodies are updating safety standards. These new guidelines ensure higher safety levels in the workplace.

- Remote Monitoring: Remote monitoring systems track electrical systems in real-time. This allows for quick response to potential hazards.

Industries are also investing in community education. By raising awareness, companies ensure safety extends beyond the workplace. This holistic approach helps in creating a culture of safety.

Frequently Asked Questions

What Is An Arc Flash?

An arc flash is a dangerous electrical explosion. It occurs when an electrical fault causes a sudden release of energy. This can result in severe injury or death.

How Does An Arc Flash Happen?

An arc flash occurs when electrical current flows through the air. This usually happens due to equipment failure or human error. It can cause serious harm.

What Are Arc Flash Hazards?

Arc flash hazards include extreme heat and pressure waves. They also involve flying shrapnel and intense light. These hazards can cause severe injuries or fatalities.

How Can You Prevent An Arc Flash?

Preventing an arc flash involves regular equipment maintenance. Following safety protocols and using appropriate PPE is crucial. Proper training for workers also helps reduce risks.

Conclusion

Understanding arc flash hazards is crucial for workplace safety. Implement protective measures to prevent accidents and ensure compliance. Regular training and proper equipment can save lives. Stay informed and prioritize safety to create a secure working environment. Remember, proactive safety measures are key to preventing arc flash incidents.