Conduit pipes protect electrical wiring and facilitate safe installations. They are crucial for both residential and commercial buildings.

Conduit pipes are essential in modern construction, providing a safeguard for electrical wiring against damage, moisture, and chemical exposure. These pipes come in various materials, such as PVC, steel, and aluminum, each offering unique benefits depending on the installation environment.

PVC conduit pipes are lightweight, resistant to corrosion, and easy to install, making them a popular choice for residential applications. On the other hand, steel conduits offer superior strength and durability, ideal for industrial settings. Proper selection and installation of conduit pipes ensure a safe, efficient, and long-lasting electrical system. Investing in quality conduit pipes enhances overall building safety and functionality.

Introduction To Conduit Pipes

Conduit pipes are essential in electrical and construction projects. They protect and route electrical wiring. These pipes ensure safety and organization in any building.

Purpose And Importance

Conduit pipes play a vital role in safeguarding electrical wires. They prevent damage from external factors like moisture and physical impact. Using conduit pipes reduces the risk of electrical hazards.

They also help in organizing cables neatly. This makes maintenance and troubleshooting easier. Conduit pipes are a must-have for any well-structured electrical system.

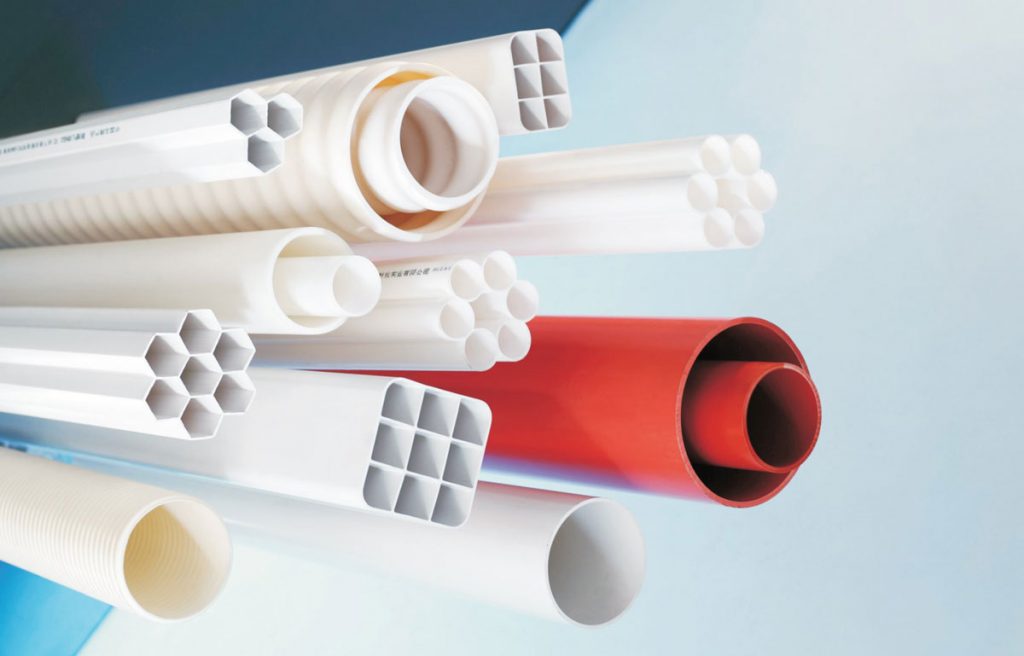

Types Of Conduit Pipes

There are several types of conduit pipes, each with specific uses. Here’s a quick overview:

- Rigid Metal Conduit (RMC): Made from steel, very strong and durable.

- Intermediate Metal Conduit (IMC): Lighter than RMC but still robust.

- Electrical Metallic Tubing (EMT): Lightweight, easy to install, and bendable.

- Flexible Metal Conduit (FMC): Allows for flexibility in tight spaces.

- Liquid-tight Flexible Metal Conduit (LFMC): Used in wet or damp locations.

- Rigid PVC Conduit: Corrosion-resistant and lightweight, made from plastic.

Each type has its own unique benefits. Choosing the right one depends on the project needs.

Credit: reganindustrial.com

Material Choices

Choosing the right conduit pipe material is crucial. Different materials offer unique benefits. These materials can impact durability, flexibility, and cost. Let’s explore the two main categories: metal conduits and non-metal conduits.

Metal Conduits

Metal conduits are known for their strength. They offer excellent protection for electrical wiring. Common types include rigid metal conduit (RMC), intermediate metal conduit (IMC), and electrical metallic tubing (EMT).

| Type | Features | Usage |

|---|---|---|

| RMC | Thick, heavy, galvanized | Outdoor, industrial |

| IMC | Thinner, lighter, still strong | Commercial, industrial |

| EMT | Thin, flexible, lightweight | Residential, commercial |

Non-metal Conduits

Non-metal conduits are lightweight and corrosion-resistant. They are also easy to install. Popular types include polyvinyl chloride (PVC) and liquid-tight flexible non-metallic conduit (LFNC).

- PVC: Affordable, easy to cut, used indoors and outdoors.

- LFNC: Flexible, waterproof, ideal for wet locations.

Both types have unique advantages. Choose based on your project needs.

Installation Guidelines

Conduit pipes ensure safe and organized wiring in buildings. Proper installation is crucial for durability and safety. Follow these guidelines for a successful installation.

Preparation Steps

Before starting the installation, ensure you have a clear plan.

- Inspect the installation area for any obstacles.

- Measure the length of conduit pipes needed.

- Mark the spots where pipes will be installed.

Preparing in advance saves time and avoids errors. Ensure the workspace is clean and clear. A clutter-free area helps in smooth installation.

Tools And Equipment

Using the right tools ensures a seamless installation process. Here is a list of essential tools:

| Tool | Purpose |

|---|---|

| Hacksaw | Cutting conduit pipes to size |

| Measuring Tape | Accurate measurements |

| Pipe Bender | Bending pipes to fit corners |

| Level | Ensuring straight installation |

| Screwdriver | Securing clamps and fittings |

Make sure all tools are in good condition. Faulty tools can cause delays and safety issues.

Credit: technotraderesources.com

Safety Considerations

Ensuring the safety of conduit pipes is crucial. This prevents accidents and ensures a reliable electrical system. Here, we will discuss key safety considerations for conduit pipes.

Avoiding Electrical Hazards

Using conduit pipes properly can avoid many electrical hazards. Follow these tips to stay safe:

- Ensure conduit pipes are properly grounded. This prevents electrical shocks.

- Avoid overloading the pipes with too many wires. This reduces the risk of overheating.

- Inspect conduit pipes regularly for wear and tear. Replace damaged pipes immediately.

- Use the right type of conduit for your environment. For example, use PVC for wet areas.

- Ensure all connections are secure. Loose connections can cause sparks.

Compliance With Codes

Compliance with electrical codes ensures safety and legality. Here are key aspects to consider:

- Follow the National Electrical Code (NEC) guidelines. This is essential for all installations.

- Local codes may vary, so check with your local authority.

- Use conduit pipes that are UL-listed. This ensures they meet safety standards.

- Ensure proper labeling of conduit pipes. This helps in identifying circuits easily.

- Hire a licensed electrician for installations. This guarantees compliance with all codes.

By following these safety considerations, you can ensure that your conduit pipes are safe and reliable.

Efficiency Benefits

Conduit pipes offer many efficiency benefits. They save energy and extend system life. This can lead to cost savings and fewer repairs. Below, we explore these benefits in detail.

Energy Conservation

Conduit pipes help in energy conservation. They reduce heat loss in electrical systems. This means your systems use less power. Here are some key points:

- Reduced heat loss

- Lower energy consumption

- Decreased utility bills

A well-insulated conduit pipe keeps electrical components cool. This enhances their efficiency. The table below shows typical energy savings:

| Type of Conduit | Energy Savings (%) |

|---|---|

| Metal Conduit | 15% |

| PVC Conduit | 10% |

System Longevity

Conduit pipes also extend system longevity. They protect wires from damage. This prevents wear and tear. Here are key benefits:

- Enhanced protection

- Reduced maintenance

- Longer system life

Using conduit pipes means fewer repairs. Your system lasts longer and performs better. This leads to fewer disruptions and lower costs.

Credit: en.lesso.com

Maintenance Tips

Maintaining conduit pipes is vital for their longevity and performance. Regular care prevents issues and keeps systems running smoothly. Here are some essential maintenance tips.

Routine Inspections

Regular inspections help identify potential issues early. Schedule inspections at least twice a year. Check for signs of wear, corrosion, or damage.

- Look for cracks or breaks in the pipes.

- Ensure all fittings are secure and tight.

- Check for any signs of rust or corrosion.

- Inspect for any blockages or obstructions.

Document your findings during inspections. Addressing minor issues early can prevent costly repairs.

Common Issues And Fixes

Knowing common issues helps in quick fixes. Here are some frequent problems and their solutions.

| Issue | Cause | Fix |

|---|---|---|

| Blockages | Debris accumulation | Clean the inside of the pipes |

| Corrosion | Moisture exposure | Apply anti-corrosion coating |

| Loose fittings | Vibration or wear | Tighten or replace fittings |

| Cracks | Physical damage | Replace damaged sections |

Use these tips to maintain conduit pipes efficiently. Regular checks and prompt fixes ensure a longer lifespan for your piping systems.

Cost Factors

Understanding the cost factors of conduit pipes is essential for any project. This section will break down the key cost considerations. We’ll examine the initial investment and the potential long-term savings.

Initial Investment

The initial cost of conduit pipes can vary. Several factors influence this cost, including:

- Material type: PVC, steel, and aluminum have different prices.

- Pipe diameter: Larger diameters generally cost more.

- Length of the pipes: Longer pipes increase the overall cost.

- Quantity needed: Buying in bulk can reduce the price per unit.

For a quick comparison, consider the table below:

| Material | Average Cost per Foot |

|---|---|

| PVC | $0.50 |

| Steel | $1.20 |

| Aluminum | $1.00 |

Long-term Savings

While initial costs are important, long-term savings are crucial too. Conduit pipes can offer significant savings over time. Here are some reasons why:

- Durability: High-quality materials last longer, reducing replacement costs.

- Maintenance: Durable pipes require less frequent maintenance.

- Energy efficiency: Insulated pipes can save on energy costs.

- Protection: Conduit pipes protect wires from damage, preventing costly repairs.

Investing in better materials initially can lead to substantial savings down the line. This makes conduit pipes a cost-effective choice for many projects.

Future Trends

The future of conduit pipes is bright and full of innovation. New technologies are changing the industry. Let’s explore some of the exciting trends.

Innovations In Materials

Material technology is evolving. Conduit pipes are now made from new materials that are stronger and lighter. These materials last longer and are more environmentally friendly.

- High-Density Polyethylene (HDPE): Durable and flexible.

- Fiberglass Reinforced Plastic (FRP): Strong and corrosion-resistant.

- PVC-O: Offers improved hydraulic performance and strength.

These materials reduce maintenance costs. They also improve the lifespan of the pipes.

Smart Conduit Systems

Smart conduit systems are the future. These systems can monitor and control the flow within the pipes. They use sensors and IoT technology.

| Feature | Benefit |

|---|---|

| Real-time Monitoring | Detect issues early. |

| Automated Controls | Optimize flow and pressure. |

| Data Analytics | Improve system performance. |

Smart systems increase efficiency. They also reduce downtime and improve safety.

Frequently Asked Questions

What Are Conduit Pipes Used For?

Conduit pipes protect and route electrical wiring in buildings. They ensure safety and organization, reducing fire risks.

Are Conduit Pipes Waterproof?

Yes, conduit pipes can be waterproof. They are designed to protect electrical wiring from moisture and environmental damage.

How To Install Conduit Pipes?

To install conduit pipes, measure and cut them to size. Then, secure them with fittings and clamps.

Can Conduit Pipes Be Used Outdoors?

Yes, conduit pipes can be used outdoors. Choose weather-resistant materials like PVC or metal for durability.

Conclusion

Conduit pipes offer excellent protection for electrical wiring. They ensure safety and durability in various environments. Choosing the right conduit pipe can prevent potential hazards and extend the life of electrical systems. Invest in quality conduit pipes for a secure and efficient electrical setup.

Stay safe and make informed decisions.