An electrician’s hammer is a specialized tool used for electrical work. It features a straight claw for precision tasks.

Electricians rely on specific tools to ensure their work is safe and efficient. One such essential tool is the electrician’s hammer. This hammer is designed with a straight claw, making it perfect for delicate tasks like pulling out nails or adjusting wires.

Its balanced weight and ergonomic handle provide comfort and control during use. Ideal for both professional electricians and DIY enthusiasts, this tool ensures precision and reduces the risk of damaging electrical components. Choosing the right hammer can significantly impact the quality of electrical installations and repairs. Investing in a high-quality electrician’s hammer is crucial for optimal performance and safety.

The Electrician’s Hammer: A Pro’s Ally

The electrician’s hammer is a vital tool for every electrician. It combines precision, durability, and efficiency. This hammer is designed to meet the unique needs of electrical work. From installing electrical boxes to securing cables, it is an indispensable asset.

Key Features

The electrician’s hammer boasts several key features that make it stand out. Here are some of the most important:

- Non-conductive handle: Ensures safety while working with electrical components.

- Balanced weight: Provides optimal control and reduces hand fatigue.

- High durability: Made from top-grade materials for long-lasting performance.

- Magnetic nail holder: Simplifies one-handed nail placement, enhancing efficiency.

Design Elements

The design of the electrician’s hammer is both practical and ergonomic. Here are some notable design elements:

| Design Element | Description |

|---|---|

| Ergonomic Grip | Provides a comfortable and secure hold. |

| Compact Size | Allows for easy access in tight spaces. |

| Shock-Absorbing Handle | Reduces impact on the user’s hand and wrist. |

| Precision Head | Ensures accurate strikes for delicate tasks. |

Electricians rely on their hammer for various tasks. These tools are engineered to be both robust and user-friendly. Whether driving nails or positioning fixtures, the electrician’s hammer delivers precision and reliability.

Differences From Standard Hammers

Electricians hammers are different from standard hammers. These unique tools are designed for specific electrical tasks. Learn the key differences that set them apart.

Weight And Balance

Electricians hammers have a lighter weight. This allows for greater precision. The balance is optimized for electrical work. It reduces fatigue during long tasks.

Standard hammers are often heavier. They are designed for general construction. The weight can cause hand strain. This makes them less ideal for delicate electrical tasks.

| Feature | Electricians Hammer | Standard Hammer |

|---|---|---|

| Weight | Lighter | Heavier |

| Balance | Optimized for precision | General use |

Face And Claw Modifications

The face of an electricians hammer is often smaller. This allows for more precise strikes. The claw is modified for pulling small nails and staples. This is common in electrical installations.

Standard hammers have a larger face. They are designed for driving large nails. The claw is made for general prying and pulling. These features are less suited for electrical tasks.

- Electricians Hammer Face: Smaller, precise

- Standard Hammer Face: Larger, general use

- Electricians Hammer Claw: Modified for small nails

- Standard Hammer Claw: General prying

Materials And Construction

An electrician’s hammer is a crucial tool for any electrical job. The materials and construction of the hammer ensure it is durable and safe.

High-quality Steel

The head of an electrician’s hammer is made of high-quality steel. This steel is strong and durable. It can withstand repeated impacts without deforming. The steel is also resistant to rust and corrosion. This ensures the hammer lasts a long time.

To maintain its quality, the steel undergoes various treatments. These include heat treatment and tempering. These processes increase the steel’s strength and hardness. As a result, the hammer can handle tough jobs without breaking.

Insulated Handles

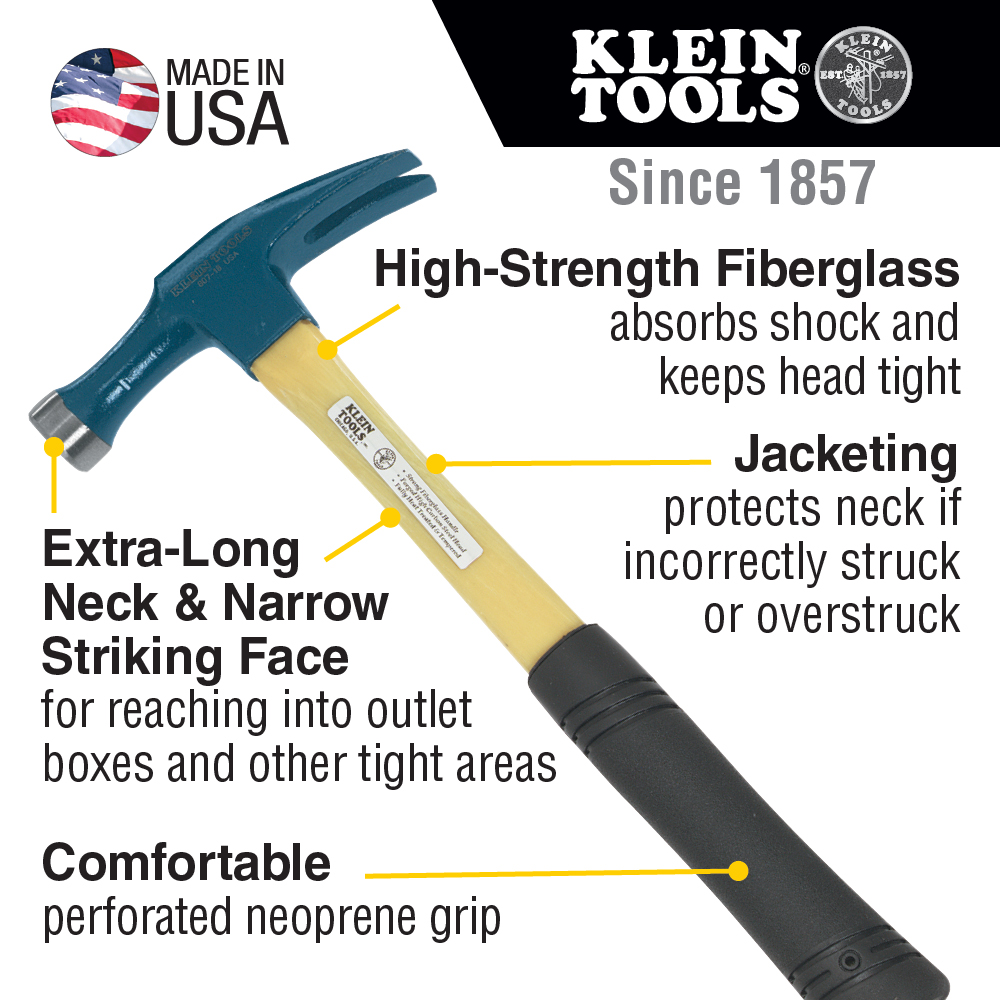

The handle of an electrician’s hammer is often made of fiberglass or rubber. These materials provide insulation. Insulation is crucial for safety. It protects electricians from electric shocks.

The handle is also ergonomically designed. This means it is comfortable to hold. A good grip reduces hand fatigue. This is important for long working hours.

| Material | Benefit |

|---|---|

| High-Quality Steel | Durable and strong |

| Fiberglass | Provides insulation |

| Rubber | Comfortable grip |

In summary, the materials and construction of an electrician’s hammer make it a reliable tool. High-quality steel and insulated handles ensure durability and safety.

Credit: www.misterworker.com

Safety Considerations

Using an electrician’s hammer requires attention to safety. Proper handling and precautions prevent accidents. Let’s explore key safety measures to keep in mind.

Shock Resistance

An electrician’s hammer must be shock resistant. This feature reduces the risk of electric shock. Hammers designed for electricians have insulated handles. These handles protect you from electrical currents.

Always check the insulation before use. Ensure it is not damaged or worn out. Replace the hammer if the insulation is compromised. Investing in a quality hammer ensures your safety.

Proper Usage Techniques

Using the hammer correctly is crucial. Follow these steps for safe use:

- Grip the hammer firmly with both hands.

- Always wear safety goggles to protect your eyes.

- Strike surfaces with controlled force.

- Avoid striking at angles to prevent slipping.

Proper technique minimizes injury risks. Practice makes perfect. Regularly inspect your hammer for any signs of wear. Replace it if necessary.

| Safety Check | Action |

|---|---|

| Insulation Intact | Safe to Use |

| Insulation Damaged | Do Not Use |

| Handle Firm | Safe to Use |

| Handle Loose | Do Not Use |

Ensuring your hammer is in good condition is critical. Follow these guidelines for safe and effective use.

Ergonomics And Comfort

Electricians often work long hours. Their tools must be comfortable. Ergonomics play a crucial role in this. An Electrician’s Hammer designed with ergonomics in mind reduces fatigue. It also prevents injuries. Let’s explore some key features.

Grip Design

The grip design of an Electrician’s Hammer is vital. A well-designed grip provides a secure hold. It should be non-slip and fit comfortably in the hand. Many hammers use rubberized grips for better control. This reduces the risk of accidents. Here’s a table showing common grip materials:

| Material | Benefits |

|---|---|

| Rubber | Non-slip, comfortable, reduces vibration |

| Leather | Durable, classic look, good grip |

| Plastic | Lightweight, affordable, varied textures |

Choosing the right grip design can improve your work efficiency. It also enhances overall comfort during prolonged use.

Vibration Dampening

Vibration dampening is another critical feature. Excessive vibration can lead to hand fatigue. It can also cause long-term injuries. Modern Electrician’s Hammers incorporate vibration dampening technology. This minimizes the impact of each strike. Some hammers have built-in shock absorbers. These features make the hammer easier to use.

Here are some common vibration dampening methods:

- Shock-absorbing handles

- Specially designed hammerheads

- Vibration-dampening materials

Using a hammer with effective vibration dampening can enhance comfort. It also improves your overall work experience.

Credit: www.amazon.com

Versatility In Electrical Work

Electricians rely on a variety of tools to perform their tasks. One indispensable tool is the electrician’s hammer. This tool is known for its versatility in electrical work. It is essential for both basic and complex electrical projects.

Applications In Wiring

The electrician’s hammer is crucial in wiring tasks. It is used to drive nails and staples into walls. This secures electrical cables in place. The hammer’s design allows for precision and control. This ensures that wires are not damaged during installation.

- Securing cables

- Installing electrical boxes

- Removing old wiring

Electricians also use the hammer for creating openings in walls. These openings are for electrical boxes and outlets. The hammer’s claw is used for pulling nails and staples. This makes it easy to remove old wiring during upgrades.

Beyond Electrical Tasks

The electrician’s hammer is not limited to electrical work. It can be used in various other tasks. This includes minor construction work and household repairs. Its sturdy design makes it suitable for multiple applications.

- Hanging pictures

- Fixing furniture

- General carpentry tasks

Having a versatile tool like the electrician’s hammer is valuable. It helps in efficiently completing a variety of tasks. This reduces the need for multiple tools. Thus, making it a must-have for any toolkit.

| Task | Use of Electrician’s Hammer |

|---|---|

| Securing Cables | Driving staples into walls |

| Installing Electrical Boxes | Creating openings in walls |

| Removing Old Wiring | Pulling nails and staples |

| Hanging Pictures | Driving nails into walls |

| Fixing Furniture | Hammering nails into wood |

Maintenance And Care

Maintaining your electrician’s hammer ensures its longevity and efficiency. Proper care keeps it in top shape for all tasks. Follow these simple guidelines for optimal performance.

Cleaning Practices

Regular cleaning prevents rust and extends the hammer’s life. After each use, wipe the hammer with a damp cloth. Remove any dirt or debris. For stubborn grime, use a mild soap solution. Avoid harsh chemicals that can damage the metal. Dry the hammer thoroughly to prevent moisture buildup.

- Wipe with a damp cloth

- Use mild soap for tough dirt

- Dry completely to avoid rust

Storage Solutions

Storing your electrician’s hammer properly prevents wear and tear. Keep it in a dry, cool place. Avoid leaving it in humid areas. Use a dedicated toolbox for safe storage. This protects the hammer from accidental damage.

Hang the hammer on a wall hook if possible. This keeps it accessible and organized. Ensure the storage area is free from moisture.

- Store in a dry, cool place

- Use a dedicated toolbox

- Hang on a wall hook if possible

Credit: www.kleintools.com

Selecting The Right Electrician’s Hammer

Choosing the right electrician’s hammer is crucial for electrical tasks. The hammer’s design, weight, and material play a significant role in its effectiveness. A good hammer ensures precision and safety. Understanding key factors helps you select the best tool for the job. Let’s dive into some important considerations.

Brand Comparisons

Different brands offer various features and benefits. Here is a comparison of popular brands:

| Brand | Features | Durability |

|---|---|---|

| Brand A | Ergonomic handle, lightweight | High |

| Brand B | Shock-absorbing grip, balanced weight | Medium |

| Brand C | Heavy-duty head, anti-rust coating | Very High |

Price Vs. Quality

Price and quality are important factors in selecting a hammer. Here is a quick comparison:

- Budget Options: Affordable but may lack durability.

- Mid-range Options: Balance between price and quality.

- Premium Options: High-quality materials and superior performance.

Investing in a quality hammer ensures longer life and better performance. A good hammer saves time and reduces strain. Consider your budget and the tool’s longevity. Choose a hammer that meets both your needs and price range.

Frequently Asked Questions

What Type Of Hammer Do Electricians Use?

Electricians typically use a claw hammer or a lineman’s hammer. These hammers provide precision and durability for electrical tasks.

What Is An Electrical Hammer?

An electrical hammer is a power tool that uses electricity to drive nails or break materials. It’s efficient and saves labor.

How Is An Electrician’s Hammer Different From A Standard Claw Hammer?

An electrician’s hammer has a straight claw and insulated handle. A standard claw hammer has a curved claw and non-insulated handle.

What Is The Best Oz Hammer For Electricians?

The best Oz hammer for electricians is the Estwing E3-16S. It features a 16-ounce head, shock reduction grip, and durable steel construction.

Conclusion

Choosing the right electrician’s hammer can make a big difference in your projects. Ensure you select one that fits your needs. Quality and comfort are key factors. Investing in a reliable electrician’s hammer will save you time and effort. Make a smart choice for better results and a smoother workflow.