The NEC mandates specific requirements for electric service and meter installations to ensure safety and reliability. These include proper grounding, clearances, and accessibility.

The National Electrical Code (NEC) provides essential guidelines for electric service and meter installations. These regulations ensure electrical systems are safe, efficient, and reliable. Proper grounding and bonding are crucial to prevent electrical hazards. Clearances must be maintained to avoid contact with other utilities and structures.

Accessibility is vital for maintenance and emergency situations. Adhering to NEC standards helps prevent electrical fires, shocks, and other dangers. Electricians and contractors must stay updated with the latest NEC revisions to comply with local codes and standards. Ensuring proper installation not only safeguards properties but also enhances overall electrical system performance.

Introduction To Nec And Its Importance

The National Electrical Code (NEC) is a standard for safe electrical design. It ensures safe installation and inspection of electrical systems. Understanding NEC is crucial for both electricians and homeowners.

Purpose Of The National Electrical Code

The NEC sets guidelines for electrical wiring and equipment. These guidelines help prevent electrical hazards. The code is updated every three years to reflect new safety practices.

- Ensures safe electrical installations

- Prevents electrical fires

- Promotes uniformity in electrical practices

Impact On Electrical Safety

The NEC has a significant impact on electrical safety. It reduces the risk of electrical shocks and fires. Compliance with the NEC protects lives and property.

| Hazard | NEC Solution |

|---|---|

| Electrical Shock | Proper grounding and bonding |

| Electrical Fire | Correct circuit protection |

Following NEC guidelines ensures a safer environment. Both professionals and DIY enthusiasts should adhere to these standards.

General Requirements For Service Installations

The General Requirements for Service Installations ensure safe and efficient electrical service. These standards are crucial for compliance with the National Electrical Code (NEC). They cover various aspects, from service entrance location to clearance standards.

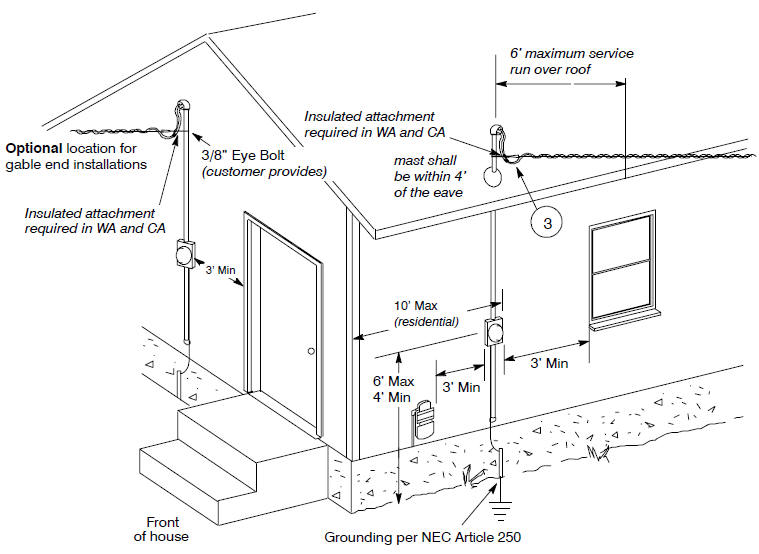

Service Entrance Location

The service entrance must be easy to access. This allows for quick inspections and repairs. The location should be free from obstacles. Install the entrance on a sturdy, weather-resistant wall. Avoid placing it near windows or vents. Ensure it is well-lit for nighttime visibility.

Proper placement reduces risks and enhances safety. Use appropriate materials to shield the entrance from environmental damage. The location must comply with local building codes.

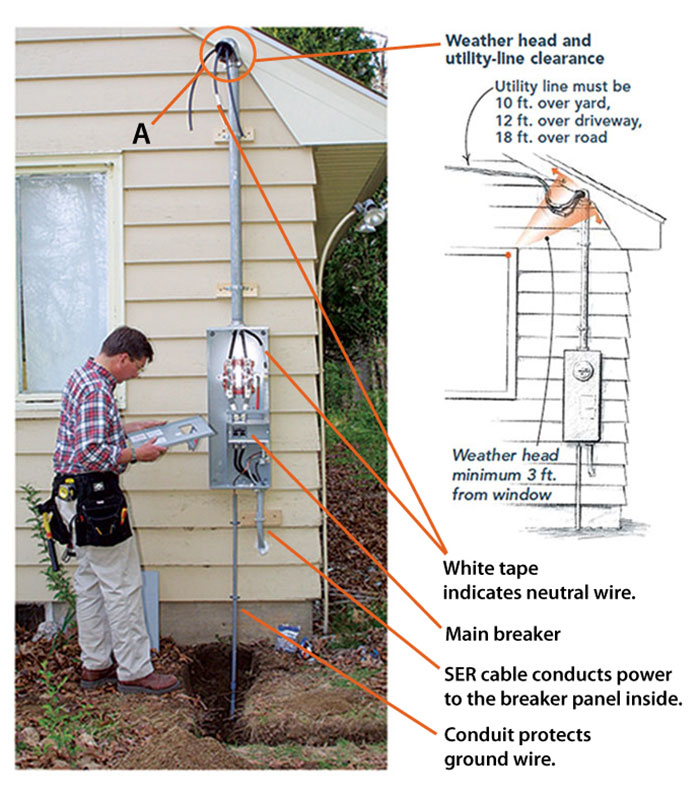

Clearance Standards

Clearance standards are vital for safety. Maintain minimum clearance around the service installation. This prevents accidents and allows easy maintenance. Follow these guidelines:

- Vertical Clearance: Minimum 10 feet above walking surfaces.

- Horizontal Clearance: At least 3 feet from windows and doors.

- Overhead Lines: Must be at least 12 feet above driveways.

Ensure the area around the service installation is clear of vegetation. Trim trees and bushes regularly. This prevents interference with electrical components. Proper clearance also helps in emergency situations.

| Type of Clearance | Minimum Distance |

|---|---|

| Vertical Clearance | 10 feet |

| Horizontal Clearance | 3 feet |

| Overhead Lines | 12 feet |

Adhering to these standards ensures a safe and compliant installation. Regularly check for any obstructions or changes in the environment. Address issues promptly to maintain safety and functionality.

Meter Installation Guidelines

Installing an electric meter requires following the NEC guidelines. Proper installation ensures safety and efficiency. Here we discuss important guidelines for installing electric meters.

Meter Socket Specifications

The meter socket is a crucial component. It houses the electric meter. To ensure safety and functionality, follow these specifications:

- Use sockets rated for outdoor use.

- Ensure the socket can handle the maximum load.

- Check the socket’s compatibility with the meter type.

- Use corrosion-resistant materials for durability.

Refer to the table below for common specifications:

| Specification | Requirement |

|---|---|

| Material | Corrosion-resistant metal |

| Rating | Outdoor use |

| Load Capacity | Max load of the service |

| Compatibility | Match meter type |

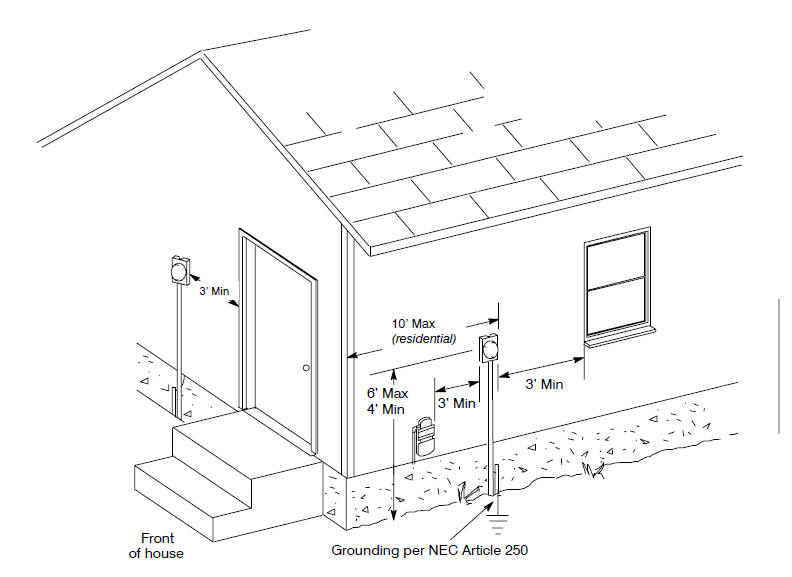

Proper Meter Placement

Placement of the meter impacts safety and accessibility. Follow these guidelines for proper placement:

- Install the meter at a height between 4 and 6 feet.

- Ensure the location is easily accessible for maintenance.

- Avoid placing the meter in hazardous areas.

- Maintain a clearance of at least 3 feet around the meter.

Proper placement ensures the meter is safe and easy to read. It also simplifies maintenance tasks.

Grounding And Bonding In Service Installations

Proper grounding and bonding in service installations is crucial. It ensures the safety of electrical systems. Understanding these requirements helps prevent electrical hazards. This section covers the essentials of effective grounding and bonding requirements for safety.

Essentials Of Effective Grounding

Effective grounding connects the electrical system to the earth. This reduces the risk of electric shock. The National Electrical Code (NEC) sets specific rules for this.

Here are some essentials:

- Grounding Electrode System: Connects the electrical system to the ground.

- Grounding Electrode Conductors: Wires that link to the grounding electrode.

- Connection Points: Securely fasten all grounding conductors.

- Resistance: Keep the resistance to earth low.

Bonding Requirements For Safety

Bonding connects various parts of the electrical system. This ensures a continuous path for electricity. It prevents potential differences that can cause electric shock.

Key bonding requirements include:

- Bonding Jumpers: Connect metal parts to the grounding system.

- Metallic Raceways: Bond all metal enclosures and conduits.

- Service Equipment: Bond all service equipment to the grounding system.

- Panelboards: Ensure all panelboards are properly bonded.

Correct grounding and bonding are vital for safety. Following NEC requirements helps maintain a secure electrical system.

Conductor Sizing And Protection

Ensuring proper conductor sizing and protection is crucial for electric service and meter installations. This process guarantees that electrical systems operate safely and efficiently. Proper sizing prevents overheating and potential hazards. Protection devices shield the system from overcurrent and short circuits.

Calculating Load Requirements

To determine the correct conductor size, you need to calculate the load requirements. This involves understanding the total electrical demand of the installation. Follow these steps:

- Identify all electrical devices and appliances.

- Note their wattage or amperage ratings.

- Calculate the total load in amperes.

Use the formula: Total Load (A) = Total Wattage (W) / Voltage (V)

For example, if you have a 240V system with 4800W total load: 4800W / 240V = 20A. Your conductor must handle at least 20A.

Overcurrent Protection Devices

Overcurrent protection devices are essential for safeguarding electrical systems. They prevent damage due to excess current.

- Fuses – Simple devices that melt under high current.

- Circuit Breakers – Switch off the circuit during overcurrent.

Choose the right device based on the conductor’s capacity. Ensure it matches the calculated load requirements.

Choosing The Right Conductor

Refer to the NEC tables to select the appropriate conductor size. Here is a simplified guide:

| Conductor Material | Size (AWG) | Maximum Amps |

|---|---|---|

| Copper | 12 | 20 |

| Aluminum | 12 | 15 |

Always use the NEC guidelines to ensure compliance and safety.

Service Equipment And Disconnects

Understanding the NEC requirements for service equipment and disconnects is crucial. These rules ensure safe and efficient electric service and meter installations. This section dives into the types and placement of main disconnects.

Main Disconnect Types

The main disconnect is essential for safety. It allows users to shut off electrical power quickly. There are three primary types:

- Fused Disconnects – These have a fuse to protect against overloads.

- Circuit Breaker Disconnects – These use a breaker to cut off power.

- Combination Units – These include both a fuse and a breaker.

Each type has specific applications. Choose the right one for your installation. Check local codes for specific requirements.

Placement And Accessibility

Placement of the main disconnect is crucial. It must be easy to reach. The NEC specifies that it should be outside or inside near the entrance.

Here are some key points:

- The disconnect must be on the first floor or basement.

- It should not be placed in bathrooms or closets.

- Ensure there is a clear path to the disconnect.

Accessibility is also important. The NEC requires that the disconnect be reachable without tools. It must be at a height of not more than 6 feet 7 inches.

These requirements ensure that anyone can operate the disconnect safely. Proper placement and accessibility are key to meeting NEC standards.

Working Space And Access For Electrical Equipment

Ensuring proper working space and access for electrical equipment is crucial. The National Electrical Code (NEC) outlines specific requirements to ensure safety. Proper space around electrical equipment helps prevent accidents and makes maintenance easier.

Minimum Working Space Dimensions

The NEC specifies minimum working space dimensions around electrical equipment. This space allows workers to move safely and perform tasks effectively.

| Voltage Range | Minimum Depth | Minimum Width | Minimum Height |

|---|---|---|---|

| 0 – 150V | 3 feet | 30 inches | 6.5 feet |

| 151 – 600V | 3.5 feet | 30 inches | 6.5 feet |

| Over 600V | 4 feet | 30 inches | 6.5 feet |

These dimensions ensure that electrical workers have enough room to work safely. Minimum depth, width, and height are crucial for safety.

Maintaining Unobstructed Access

Unobstructed access to electrical equipment is essential. The NEC mandates that no items block access to electrical panels or meters.

- No storage within the working space.

- Doors or panels should open fully.

- Equipment labels must remain visible at all times.

No storage within the working space ensures clear paths. Doors or panels should open fully to allow quick access. Keeping labels visible ensures identification during emergencies.

Common Code Violations And Compliance

Understanding the National Electrical Code (NEC) is crucial for safe installations. Many electricians overlook critical details, leading to common code violations. In this section, we will highlight frequent mistakes and ways to ensure compliance.

Frequent Installation Mistakes

Electricians often make errors during electric service and meter installations. These mistakes can be costly and dangerous. Below are some frequent installation mistakes:

- Improper grounding and bonding

- Using incorrect wire sizes

- Failing to install disconnects

- Incorrectly positioning the meter

Improper grounding and bonding: This can lead to electrical hazards. Ensure all grounding and bonding meet NEC standards.

Using incorrect wire sizes: Wrong wire sizes can cause overheating. Always refer to NEC guidelines for the correct wire size.

Failing to install disconnects: Disconnects are vital for safety. Install them as per NEC rules to avoid violations.

Incorrectly positioning the meter: Meter placement must follow NEC codes. Incorrect placement can result in accessibility issues.

Ensuring Code Compliance

Ensuring NEC compliance is essential for safety and efficiency. Here are steps to ensure compliance:

- Follow the latest NEC guidelines

- Use proper materials and equipment

- Regularly inspect installations

- Keep up with code updates

Follow the latest NEC guidelines: Always refer to the most recent NEC edition. This ensures you meet current standards.

Use proper materials and equipment: High-quality materials reduce risks. Ensure all components meet NEC specifications.

Regularly inspect installations: Frequent inspections help identify issues early. This ensures continuous compliance.

Keep up with code updates: The NEC updates regularly. Stay informed about changes to maintain compliance.

| Common Violations | Compliance Tips |

|---|---|

| Improper grounding | Follow NEC grounding guidelines |

| Wrong wire size | Use NEC-recommended wire sizes |

| Missing disconnects | Install disconnects as per NEC |

| Incorrect meter placement | Position meters according to NEC |

By avoiding common mistakes and following NEC guidelines, you can ensure safe and compliant installations.

Updates And Changes In The Latest Nec Edition

The National Electrical Code (NEC) frequently updates its guidelines. These changes ensure safety and efficiency in electrical installations. The latest NEC edition includes several important updates. These updates impact electric service and meter installations.

Recent Amendments

The latest NEC edition has introduced new amendments. These amendments address modern needs and technologies. Here are some key changes:

- Arc-fault Circuit Interrupters (AFCIs): Expanded requirements for AFCIs in residential installations.

- Ground-Fault Circuit Interrupters (GFCIs): Increased GFCI protection in various areas.

- Service Disconnects: New rules for service disconnect locations.

These amendments aim to enhance safety and prevent electrical hazards. They reflect advancements in technology and industry practices.

Adapting To New Standards

Electricians and contractors must adapt to these new standards. Compliance ensures installations meet current safety requirements. Here are some steps to adapt:

- Stay Informed: Regularly review the latest NEC updates.

- Training: Participate in training programs for updated practices.

- Inspection: Conduct thorough inspections to ensure compliance.

Adapting to these standards is crucial. It ensures safe and efficient electrical systems.

| Amendment | Description |

|---|---|

| AFCIs | Expanded requirements in residential installations. |

| GFCIs | Increased protection in various areas. |

| Service Disconnects | New rules for disconnect locations. |

These changes highlight the NEC’s commitment to safety. They ensure that electrical systems remain reliable and secure.

Credit: yourpowerpro.com

Safety Inspections And Permitting Process

Understanding the NEC requirements for electric service and meter installations is vital. Safety inspections and the permitting process play a crucial role. They ensure that installations meet safety standards and regulations. This section will break down the key aspects of inspections and permits.

Inspection Checkpoints

Inspections are crucial for ensuring safety and compliance. Inspectors check several points:

- Proper grounding and bonding.

- Correct wire sizing and insulation.

- Suitable circuit breaker ratings.

- Proper installation of meter sockets.

- Compliance with NEC codes.

Inspectors will verify that all connections are tight and secure. They will also check for any signs of wear or damage. Ensuring these checkpoints can prevent future hazards.

Inspection Checkpoints

Permits are essential for any electric service installation. The process involves several steps:

- Submit application to local authorities.

- Provide detailed plans of the installation.

- Pay the required fees.

- Schedule the inspection date.

- Get approval from inspectors.

Each step is crucial for a smooth installation process. Proper documentation and compliance ensure faster approvals. Always keep all records in a safe place.

Following these guidelines ensures a safe and compliant electrical system. It helps in avoiding future issues and ensures safety.

Professional Training And Nec Certification

Electricians must understand the National Electrical Code (NEC) for safe installations. The code guides electric service and meter installations. Professional training and NEC certification are crucial for compliance and safety.

Benefits Of Nec Training

NEC training enhances electricians’ skills and knowledge. It ensures they follow safety standards. This training reduces the risk of electrical hazards. Proper training also improves job performance and boosts confidence.

- Safety: Electricians learn to prevent accidents.

- Compliance: Ensures adherence to regulations.

- Efficiency: Trained electricians complete tasks quickly.

- Career Growth: Certification opens up job opportunities.

Certification Pathways For Electricians

Becoming NEC certified involves several steps. Electricians can choose from different pathways depending on their experience.

- Complete a high school diploma or GED.

- Enroll in an accredited electrical training program.

- Gain hands-on experience through apprenticeships.

- Pass the NEC certification exam.

Each step prepares electricians for real-world scenarios. They learn about wiring, installations, and safety protocols.

Credit: www.tvetacademy.org

Conclusion: The Future Of Electrical Safety

The future of electrical safety is evolving rapidly. New standards and practices are shaping the industry. The goal is to protect lives and properties. It ensures reliable and safe electrical service.

Evolving Standards

Electrical standards are not static. They change with technology advancements. The National Electrical Code (NEC) is updated every three years. These updates reflect new safety measures and technologies.

| NEC Edition | Key Updates |

|---|---|

| 2017 | Introduced new requirements for solar power systems. |

| 2020 | Updated rules for electric vehicle charging stations. |

| 2023 | Enhanced safety for battery energy storage systems. |

Continuous Improvement In Electrical Practices

Electrical practices are continuously improving. Electricians and engineers receive ongoing training. This training covers the latest NEC updates and best practices. Safety is a top priority in all installations.

- Adopt the latest NEC standards.

- Use updated tools and technologies.

- Ensure all installations meet safety guidelines.

By following these practices, the industry ensures safe and reliable electrical service for everyone.

Credit: www.finehomebuilding.com

Frequently Asked Questions

How Much Clearance Is Required Around An Electric Meter?

A minimum of 3 feet clearance is required in front of an electric meter. Ensure 1 foot clearance on the sides and above.

What Is The Nec Code For Electrical Installation?

The NEC code for electrical installations is the National Electrical Code (NEC), also known as NFPA 70. It sets safety standards for wiring and electrical systems in the U. S. The code updates every three years to incorporate new safety technologies and practices.

How Far Can An Electrical Panel Be From A Meter?

An electrical panel should be within 6 feet of the meter, but local codes may vary. Always check with local regulations.

How Far Does An Electric Meter Have To Be From A Window?

An electric meter should be at least 3 feet away from a window. This ensures safety and proper functionality.

Conclusion

Understanding NEC requirements is crucial for safe electric service and meter installations. Compliance ensures safety and efficiency. Always refer to the latest NEC guidelines. Proper installation reduces risks and promotes reliable electrical systems. Stay informed and prioritize safety for all electrical projects.

Remember, adherence to NEC standards is essential for every installation.