**What is Megger Testing? ** Megger testing measures the insulation resistance of electrical components.

It ensures the safety and efficiency of electrical systems. **** Megger testing is crucial in maintaining electrical systems’ integrity. Electricians and engineers use it to detect insulation deterioration. Proper insulation prevents electrical failures and hazards. This test identifies issues before they escalate into major problems.

Megger testing is vital for industrial, commercial, and residential setups. It involves applying a high-voltage DC to measure resistance. High insulation resistance indicates good insulation. Low resistance signals potential faults or risks. Regular Megger testing prolongs the lifespan of electrical equipment. It also ensures compliance with safety standards and regulations. This preventive measure saves costs related to repairs and downtime.

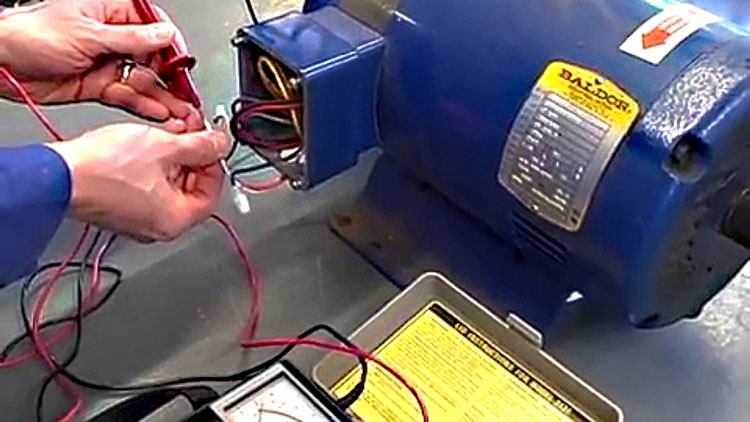

Credit: www.youtube.com

Introduction To Megger Testing

Megger Testing is a method used to measure electrical insulation. It helps in identifying insulation resistance in electrical devices. This test ensures that equipment is safe and functional. Electrical engineers use Megger Testing frequently.

Purpose Of Megger Testing

The main purpose of Megger Testing is to ensure electrical safety. It checks the insulation resistance between conductors. This test helps in preventing electrical shocks and fires. By measuring resistance, it detects any faults in the insulation. This is crucial for maintaining the reliability of electrical equipment.

Here are some key purposes of Megger Testing:

- Identify insulation failures

- Prevent electrical hazards

- Ensure equipment longevity

- Maintain safety standards

Importance In Electrical Safety

Megger Testing plays a vital role in electrical safety. Poor insulation can cause severe accidents. This test helps in identifying potential risks early. It ensures that electrical systems are safe to use. Regular testing can prevent accidents and save lives.

Importance of Megger Testing in electrical safety includes:

- Prevents electrical shocks

- Avoids equipment damage

- Ensures compliance with safety standards

- Detects insulation deterioration

In summary, Megger Testing is essential for electrical safety. It helps in maintaining the integrity of electrical systems. Regular testing ensures the safety and reliability of electrical equipment.

Credit: automationforum.co

Types Of Megger Tests

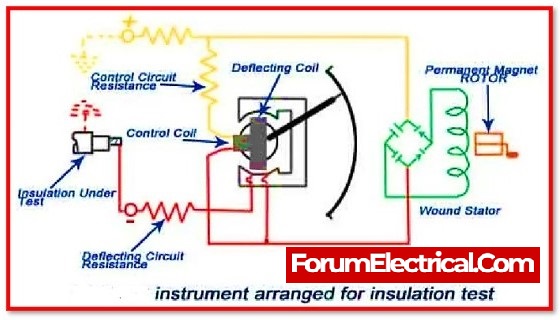

Megger testing is essential for assessing the health of electrical insulation. Different types of Megger tests cater to various needs, ensuring comprehensive analysis. Here, we explore two primary types: Insulation Resistance Test and Dielectric Absorption Ratio.

Insulation Resistance Test

The Insulation Resistance Test measures the resistance between electrical components and the ground. High resistance indicates good insulation. Low resistance suggests potential issues. This test helps identify faults in electrical installations.

To perform this test, connect the Megger device to the circuit. Apply a voltage and measure the resistance. Record the results for future reference. This test is quick and straightforward.

Here is a simple breakdown:

| Step | Description |

|---|---|

| 1 | Connect Megger to the circuit. |

| 2 | Apply voltage. |

| 3 | Measure resistance. |

| 4 | Record results. |

Dielectric Absorption Ratio

The Dielectric Absorption Ratio (DAR) measures insulation quality over time. It compares resistance readings at different intervals. Usually, the intervals are 30 seconds and 60 seconds.

A high DAR indicates good insulation. A low DAR suggests deterioration. This test is crucial for long-term equipment health.

Follow these steps for DAR:

- Connect Megger to the circuit.

- Apply voltage for 30 seconds.

- Record resistance.

- Apply voltage for 60 seconds.

- Record resistance again.

- Calculate the ratio of the two readings.

This test helps detect moisture and other contaminants. It ensures reliable performance of electrical systems.

How Megger Testing Works

Megger testing is a method used to measure the electrical resistance of insulation. It ensures the safety and efficiency of electrical systems. Understanding how Megger testing works is crucial for anyone involved in electrical maintenance.

Basic Principles

The basic principle of Megger testing involves applying a high voltage to the insulation. This helps measure its resistance. The test identifies any weaknesses or faults in the insulation material. This process helps ensure that the electrical system is safe and functional.

Key Components

The main components of a Megger tester include:

- Power Source: Provides the necessary voltage for testing.

- Insulation Resistance Meter: Measures the resistance of the insulation.

- Test Leads: Connect the tester to the electrical system.

- Display: Shows the resistance value.

These components work together to provide accurate measurements. The power source generates the required voltage. The insulation resistance meter then measures the resistance. The test leads ensure a secure connection. Finally, the display shows the results.

Understanding these components and their functions is essential. It helps ensure accurate and reliable Megger testing.

Preparation For Megger Testing

Megger testing is crucial for ensuring electrical insulation quality. Proper preparation is essential for accurate and safe results. This section covers the necessary steps to take before performing Megger testing.

Safety Precautions

Safety is the top priority. Always follow these precautions:

- Wear protective gear: Use gloves and safety glasses.

- Verify equipment: Ensure the equipment is in good condition.

- Disconnect power: Make sure all power sources are off.

- Check surroundings: Ensure a dry and clean testing area.

- Avoid flammable materials: Keep away from any flammable objects.

Equipment Checklist

Having the right equipment is crucial. Here’s a checklist for Megger testing:

| Equipment | Purpose |

|---|---|

| Megger tester | Measures insulation resistance |

| Test leads | Connects Megger to the equipment |

| Protective gear | Ensures safety during testing |

| Insulation mat | Prevents electrical shocks |

| Documentation tools | Records test results |

Ensure all items are in good condition before starting the test.

Performing A Megger Test

Megger testing checks insulation resistance in electrical devices. It ensures safety and prevents failures. Understanding this process is essential for effective testing.

Step-by-step Guide

- Prepare the equipment: Ensure the Megger tester is calibrated and functional.

- Disconnect power: Turn off and isolate the equipment to be tested.

- Connect the Megger: Attach the Megger leads to the insulation points.

- Set the voltage: Choose the appropriate test voltage for your equipment.

- Perform the test: Press the test button and read the insulation resistance value.

- Record results: Document the readings for future reference.

- Interpret results: Compare with standard values to determine insulation health.

Common Mistakes To Avoid

- Ignoring calibration: Always check the Megger’s calibration before use.

- Not isolating equipment: Ensure the device is completely disconnected from power.

- Incorrect voltage selection: Use the correct test voltage to avoid damage.

- Inadequate connection: Ensure the Megger leads are securely attached.

- Misinterpreting results: Understand how to read and analyze the insulation resistance values.

Interpreting Test Results

Interpreting test results from a Megger test is crucial. It helps ensure electrical insulation is intact and safe. Knowing how to read and understand the data is essential. This section will guide you through the process.

Understanding Readings

The Megger test provides readings in megaohms (MΩ). Higher values mean better insulation. Here’s how to interpret the readings:

- 0-1 MΩ: Poor insulation, immediate action needed.

- 1-2 MΩ: Marginal insulation, monitor closely.

- 2-5 MΩ: Fair insulation, may need maintenance soon.

- 5-100 MΩ: Good insulation, no immediate action required.

- 100+ MΩ: Excellent insulation, system is in great condition.

Troubleshooting Issues

If your readings are low, it’s time to troubleshoot. Follow these steps:

- Check for visible damage on cables and connections.

- Ensure all connections are secure and tight.

- Inspect for moisture or dirt around electrical components.

- Use a different Megger to verify results.

- Consult a professional if issues persist.

Keep a detailed log of all readings and actions taken. This helps track the health of your electrical systems over time.

Applications Of Megger Testing

The Megger Test is essential for assessing electrical insulation. It has wide-ranging applications in both industrial and residential settings. This test ensures electrical systems remain safe and reliable.

Industrial Uses

Megger testing is crucial in industrial environments. It helps maintain electrical equipment and systems. Here are some industrial applications:

- Testing high-voltage equipment

- Assessing insulation in motors and transformers

- Evaluating circuit breakers and cables

- Verifying electrical installations in factories

Industries rely on Megger testing for equipment safety. It helps prevent electrical failures and downtime.

Residential Applications

Megger testing is not just for industries. It is also useful in residential settings. Here are some common uses:

- Checking home electrical wiring

- Testing insulation of household appliances

- Ensuring the safety of residential electrical installations

Homeowners use Megger testing to ensure electrical safety. It helps prevent accidents and electrical fires.

Advantages And Limitations

Megger testing is essential for ensuring electrical systems’ reliability. It helps detect insulation failures that could cause severe problems. While it has many benefits, it also comes with some limitations. Understanding both aspects can help you make the best use of this testing method.

Benefits Of Megger Testing

- Accurate Results: Megger testing provides precise readings of insulation resistance.

- Early Detection: Helps find potential issues before they become major problems.

- Safety: Reduces the risk of electrical shocks and fires.

- Cost-Effective: Prevents costly repairs by identifying faults early.

- Easy to Use: Simple to operate, even for beginners.

Potential Drawbacks

- High Initial Cost: Megger testers can be expensive to purchase.

- Limited to Insulation: Only tests insulation, not other electrical issues.

- Requires Skilled Personnel: Accurate interpretation needs trained professionals.

- Time-Consuming: Testing large systems can take a lot of time.

- Environmental Factors: Humidity and temperature can affect readings.

Future Trends In Megger Testing

The future of Megger testing is promising. Advances in technology are improving efficiency. New practices are emerging, making testing easier and faster. This section explores these exciting trends.

Technological Advancements

Technological advancements are driving changes in Megger testing. One key development is the integration of IoT (Internet of Things). IoT enables remote monitoring and data collection. This makes testing more accurate and efficient.

Another advancement is the use of AI (Artificial Intelligence). AI can analyze test results quickly. It can also predict potential issues before they occur. This helps in preventing costly repairs and downtime.

The development of wireless Megger testers is another trend. These devices offer greater flexibility and ease of use. They also reduce the risk of human error during testing.

Emerging Practices

New practices are emerging in Megger testing. One such practice is the use of predictive maintenance. Predictive maintenance uses data from Megger tests to predict equipment failure. This allows for timely maintenance, reducing downtime.

Another emerging practice is the integration of cloud-based data storage. This allows for easy access and analysis of test data. It also ensures that data is secure and easily retrievable.

The adoption of green testing methods is also on the rise. These methods aim to reduce the environmental impact of testing. This includes using eco-friendly materials and energy-efficient devices.

In summary, the future of Megger testing is bright. Technological advancements and emerging practices are making it more efficient, accurate, and environmentally friendly.

Credit: forumelectrical.com

Frequently Asked Questions

What Is Megger Testing Used For?

Megger testing is used to measure insulation resistance in electrical equipment. It ensures the safety and reliability of electrical systems.

How Does A Megger Tester Work?

A Megger tester applies a high voltage to measure resistance. It checks for leakage currents and insulation quality.

Why Is Megger Testing Important?

Megger testing is important for preventing electrical failures. It helps identify insulation problems before they cause equipment damage.

How Often Should Megger Testing Be Done?

Megger testing should be done regularly, typically annually. Frequency may vary based on equipment and usage conditions.

Conclusion

Megger testing is crucial for ensuring electrical system safety and reliability. It helps detect insulation faults early. Regular testing can prevent costly repairs and downtime. By understanding and implementing Megger testing, you can maintain efficient and safe electrical operations. Prioritize Megger testing to enhance your system’s longevity and performance.