An Electrical Safety Analyzer tests and verifies the safety of electrical devices and equipment. It ensures compliance with safety standards.

Electrical Safety Analyzers play a crucial role in safeguarding users and maintaining equipment integrity. They measure parameters like voltage, current, resistance, and insulation quality. These devices are essential in industries such as healthcare, manufacturing, and consumer electronics. Regular testing prevents electrical hazards, reduces downtime, and ensures compliance with regulatory standards.

By identifying potential issues early, these analyzers help in maintaining a safe operational environment. Their use is vital for both new installations and routine maintenance checks. Investing in a reliable Electrical Safety Analyzer is a proactive step in enhancing workplace safety and equipment performance.

Credit: www.flukebiomedical.com

The Role Of Electrical Safety Analyzers

Electrical Safety Analyzers play a crucial role in ensuring the safety of electrical devices. These tools test and verify that equipment meets safety standards. They help identify potential hazards and ensure compliance. This keeps users safe from electrical accidents. Below, we explore the key roles these analyzers play.

Ensuring Compliance With Standards

Electrical Safety Analyzers verify that devices comply with industry standards. These standards ensure that electrical products are safe for use. They include guidelines for insulation, grounding, and leakage currents. Compliance reduces the risk of electrical shocks and fires.

Using these analyzers, manufacturers can test their products before they reach the market. This ensures the products are safe and reliable. Regulatory bodies also use these tools during inspections. They check if equipment in use meets the required safety standards.

Preventing Electrical Accidents

Electrical Safety Analyzers help in preventing electrical accidents. They detect faults in electrical systems and equipment. Early detection of these faults can prevent serious accidents.

Some common faults include insulation breakdown, grounding issues, and high leakage currents. These faults can cause electric shocks or fires. Regular testing with safety analyzers can identify these issues early. This allows for timely repairs and maintenance.

In hospitals, these tools ensure medical devices are safe. For example, they test patient monitors and life-support machines. This ensures these critical devices do not pose a risk to patients.

| Key Benefits | Description |

|---|---|

| Compliance | Ensures products meet safety standards. |

| Accident Prevention | Detects faults early to prevent accidents. |

| Safety Assurance | Keeps users safe from electrical hazards. |

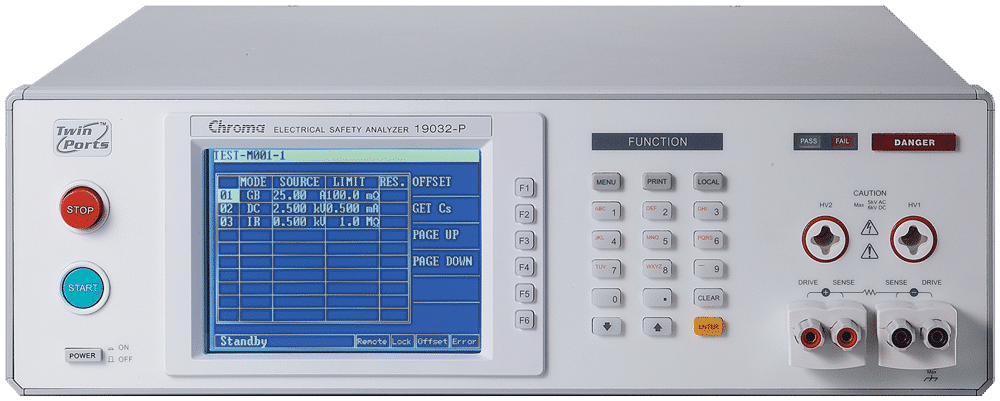

Credit: www.chromausa.com

Key Features Of Top Electrical Safety Analyzers

Understanding the key features of top Electrical Safety Analyzers is essential. These devices ensure electrical equipment operates safely. They help prevent accidents and maintain compliance with safety standards. Let’s dive into some crucial features that make these analyzers stand out.

User Interface And Accessibility

A user-friendly interface is crucial for any safety analyzer. The best analyzers have clear, easy-to-read displays. This helps users understand the data quickly. Many devices feature touchscreens, which are intuitive to use.

Accessibility is also important. Top analyzers offer multiple language options. They also provide clear instructions and help menus. This ensures that users of all skill levels can operate the device effectively.

- Clear displays for easy data reading

- Touchscreens for intuitive navigation

- Multiple language options for diverse users

- Help menus for quick guidance

Testing Capabilities And Functions

Top electrical safety analyzers offer a wide range of testing capabilities. They can perform multiple tests to ensure safety. These tests include ground bond, insulation resistance, and leakage current.

Advanced models can also test for electrical strength and polarity. They provide accurate and reliable results. This ensures that equipment meets safety standards.

| Test Type | Purpose |

|---|---|

| Ground Bond | Checks the integrity of grounding |

| Insulation Resistance | Measures resistance of insulating materials |

| Leakage Current | Detects unwanted current leakage |

| Electrical Strength | Tests the voltage withstand capability |

| Polarity | Ensures correct wiring connections |

These capabilities ensure comprehensive safety checks. They help maintain the highest standards of electrical safety.

Types Of Electrical Safety Tests

Electrical safety tests ensure devices are safe. They protect users from electrical hazards. Various tests check different aspects of safety. Let’s explore some key types of electrical safety tests.

Insulation Resistance Test

The Insulation Resistance Test measures the quality of insulation. It ensures insulation is not damaged. This test applies a voltage to the insulation. The resistance is then measured. High resistance means good insulation. Low resistance indicates possible faults.

Earth Bond Testing

Earth Bond Testing checks the connection between metal parts and the earth. This ensures any electrical fault is safely discharged to the ground. It measures the resistance of the earth connection. A low resistance value is needed for safety.

Leakage Current Testing

The Leakage Current Test measures the current that leaks from the device. This is important for user safety. High leakage current can be dangerous. The test measures the current flowing through the insulation. It ensures the device is safe to use.

Choosing The Right Electrical Safety Analyzer

Choosing the right Electrical Safety Analyzer ensures safety and compliance. These devices test electrical equipment for faults and hazards. The right analyzer can save time and prevent accidents. Here, we discuss key factors to consider.

Application-specific Considerations

Different industries have different needs. Hospitals need analyzers for medical devices. Factories need them for heavy machinery. Identify your specific use case.

- Medical Equipment: Needs precise and reliable testing.

- Industrial Machinery: Requires robust and durable analyzers.

- Consumer Electronics: Needs quick and easy-to-use devices.

Ensure the analyzer meets industry standards. Check for certifications like IEC, ANSI, and ISO.

Cost Vs. Performance

Balancing cost and performance is crucial. High-end analyzers offer more features. Basic models are more affordable. Consider your budget.

| Feature | Basic Model | High-End Model |

|---|---|---|

| Accuracy | Moderate | High |

| Durability | Standard | Enhanced |

| Additional Features | Limited | Extensive |

Choose based on your specific needs. Do you need extra features? Or is a basic model enough?

Remember, the right balance ensures value for money. Avoid overspending on unnecessary features.

Integration In Safety Protocols

Incorporating an Electrical Safety Analyzer into safety protocols is crucial for preventing accidents. This device checks electrical equipment for faults, ensuring a safe environment. It is vital for both routine checks and emergency plans.

Routine Checks And Maintenance

Regular use of an Electrical Safety Analyzer is essential. These checks ensure that all equipment is safe and functioning correctly.

- Verify grounding integrity

- Check insulation resistance

- Assess leakage currents

Routine maintenance minimizes risks and prolongs equipment lifespan. Keeping a log of these checks is also important.

| Check Type | Frequency | Action |

|---|---|---|

| Grounding Integrity | Monthly | Inspect and record |

| Insulation Resistance | Quarterly | Test and log results |

| Leakage Currents | Bi-Annually | Measure and report |

Emergency Response Planning

An Electrical Safety Analyzer is vital during emergencies. It helps identify faulty equipment quickly, ensuring prompt action.

- Isolate faulty equipment

- Perform quick tests with the analyzer

- Take corrective measures based on results

Emergency response teams should be trained to use these analyzers. This ensures quick and effective action during crises.

Incorporating the analyzer into emergency plans can save lives and property. It adds a layer of safety and reliability.

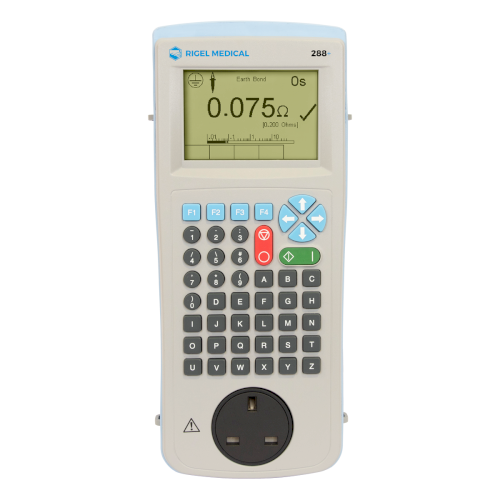

Credit: www.rigelmedical.com

Case Studies: Electrical Safety Analyzers In Action

Electrical Safety Analyzers (ESAs) are crucial for ensuring equipment safety. They detect electrical faults before they become hazards. Let’s explore how ESAs perform in real-world scenarios.

Industrial Applications

In factories, machinery operates continuously. Safety is vital to prevent accidents. An electrical safety analyzer can inspect equipment regularly.

- Automobile Manufacturing: ESAs test robotic arms and conveyors.

- Food Processing: Ensure mixers and ovens are safe.

- Textile Industry: Analyze looms and dyeing machines.

These industries rely on ESAs for compliance. They ensure all equipment meets safety standards.

| Industry | Equipment Tested | Frequency |

|---|---|---|

| Automobile | Robotic Arms | Monthly |

| Food Processing | Ovens | Quarterly |

| Textile | Looms | Monthly |

Healthcare Facility Safety

Hospitals use various electrical devices. Patient safety is a top priority. ESAs check medical equipment to ensure they are safe.

- Patient Monitors: Ensure accurate readings without electrical faults.

- MRI Machines: Regular checks to prevent malfunctions.

- Surgical Tools: Verify the safety of electrically powered instruments.

ESAs are essential in healthcare settings. They prevent equipment failures that could harm patients.

| Medical Device | Frequency | Checked Parameters |

|---|---|---|

| Patient Monitor | Monthly | Electrical Safety, Accuracy |

| MRI Machine | Quarterly | Electrical Safety, Functionality |

| Surgical Tools | Weekly | Electrical Safety, Performance |

Regular checks with ESAs save lives. They help maintain high standards of care.

Best Practices For Electrical Safety Analyzer Usage

Using an Electrical Safety Analyzer correctly ensures safety and accuracy. These best practices will help you get the most from your device.

Regular Calibration And Testing

Regular calibration is vital for any Electrical Safety Analyzer. It ensures the device provides accurate readings. Follow the manufacturer’s instructions for calibration frequency.

| Frequency | Action |

|---|---|

| Monthly | Basic checks and adjustments |

| Quarterly | Full calibration |

| Annually | Comprehensive testing and servicing |

Testing your analyzer regularly ensures it works well. Run a self-test before every major use. This helps catch issues early.

Operator Training

Training operators is key to safe and effective use. Make sure every user understands the Electrical Safety Analyzer features. Provide hands-on training sessions.

- Basics of operation

- Reading and interpreting results

- Safety protocols

Certified training programs can be very beneficial. They provide detailed knowledge and practical skills. Always update training materials with the latest information.

Future Of Electrical Safety Testing

The future of electrical safety testing is promising with new advancements. These changes will enhance safety, efficiency, and compliance. Let’s explore the exciting developments ahead.

Technological Advancements

Technology is evolving rapidly in the field of electrical safety testing. New tools and devices are emerging to make testing more accurate and efficient. One such advancement is the integration of AI and machine learning in safety analyzers.

AI can predict potential failures before they occur. This helps in preventing accidents and ensuring safety. Machine learning algorithms can analyze large datasets quickly and accurately. This leads to more precise testing results.

Another key development is the use of IoT (Internet of Things). IoT-enabled devices can communicate with each other in real-time. This allows for continuous monitoring and instant reporting of any issues.

These technological advancements are revolutionizing the way electrical safety testing is conducted. They are making the process faster, safer, and more reliable.

Regulatory Changes And Impacts

Regulations play a crucial role in electrical safety testing. They ensure that all devices meet safety standards. Recently, there have been significant changes in these regulations.

One major change is the stricter enforcement of safety standards. This means that all electrical devices must undergo rigorous testing. These tests ensure they are safe for use.

Another important change is the introduction of new safety protocols. These protocols are designed to address emerging risks and challenges. They ensure that safety testing stays up-to-date with the latest advancements.

The impact of these regulatory changes is profound. They ensure that all electrical devices are thoroughly tested and safe to use. This protects consumers and enhances overall safety.

Below is a summary of key regulatory changes and their impacts:

| Regulatory Change | Impact |

|---|---|

| Stricter Safety Standards | Increased safety and reliability |

| New Safety Protocols | Address emerging risks |

| Frequent Compliance Audits | Ensure continuous adherence to standards |

These regulatory changes are shaping the future of electrical safety testing. They are ensuring that testing processes are rigorous and effective.

Frequently Asked Questions

What Are Electrical Safety Analyzers?

Electrical safety analyzers test and ensure the safety of electrical equipment. They measure parameters like voltage, current, and insulation resistance. These devices help prevent electrical hazards and ensure compliance with safety standards.

How Do You Measure Electrical Safety?

Electrical safety is measured using insulation resistance tests, grounding tests, and equipment leakage current tests. Regular maintenance and inspections are crucial.

How Much Is The Fluke Esa620?

The Fluke ESA620 typically costs around $5,000 to $7,000. Pricing may vary based on retailer and location.

What Is The Test For Electrical Safety Device?

The test for an electrical safety device involves checking for proper grounding, insulation resistance, and functionality. This ensures safety and compliance.

Conclusion

Ensuring electrical safety is crucial for any facility. An electrical safety analyzer helps identify potential hazards. It ensures compliance with safety standards. Regular use can prevent accidents and equipment damage. Invest in a reliable analyzer to protect both personnel and devices.

Prioritize safety and efficiency in your operations.