Electrical cables are vital for transmitting electricity and data. They consist of conductors, insulation, and protective layers.

Electrical cables play a crucial role in modern infrastructure, powering homes, offices, and industries. These cables come in various types, each designed for specific applications, such as power distribution, telecommunications, and electronics. Copper and aluminum are the most common conductors due to their excellent electrical properties.

Insulation materials, like PVC or rubber, protect the conductors and ensure safety. Proper selection of electrical cables ensures efficient energy transfer and minimizes the risk of electrical hazards. Understanding the different types and their uses can help in making informed decisions for both residential and commercial projects. Quality cables not only enhance performance but also ensure longevity and safety.

The Importance Of Electrical Cables

Electrical cables are essential in our daily lives. They power our homes, offices, and many devices. Without them, we would be in the dark. They ensure the smooth flow of electricity and keep us connected.

Ensuring Safe And Reliable Power Transmission

Electrical cables are designed to be safe. They protect us from electric shocks and fires. High-quality cables ensure reliable power transmission. Poor quality cables can cause dangerous situations.

To ensure safety, cables must be properly insulated. This prevents electricity from escaping. It also protects the cables from damage. Durable materials are used for insulation, like PVC and rubber.

There are many types of electrical cables. Each type has a specific use. Below is a table showing some common types:

| Type of Cable | Use |

|---|---|

| Coaxial Cable | Television and internet |

| Twisted Pair Cable | Telephones and networking |

| Fiber Optic Cable | High-speed internet |

| Power Cable | Electrical appliances |

Coaxial cables are used for TV and internet. They are durable and can carry high-frequency signals. Twisted pair cables are common in telephones and networking. They reduce electromagnetic interference.

Fiber optic cables offer high-speed internet. They are made of thin glass fibers. Power cables are used in home appliances. They carry electricity from the power source to the device.

Types Of Electrical Cables

Electrical cables are essential for transmitting power and signals. They come in various types, each suited for different applications. Understanding the types of electrical cables helps in choosing the right one for your needs.

Understanding Different Cable Materials

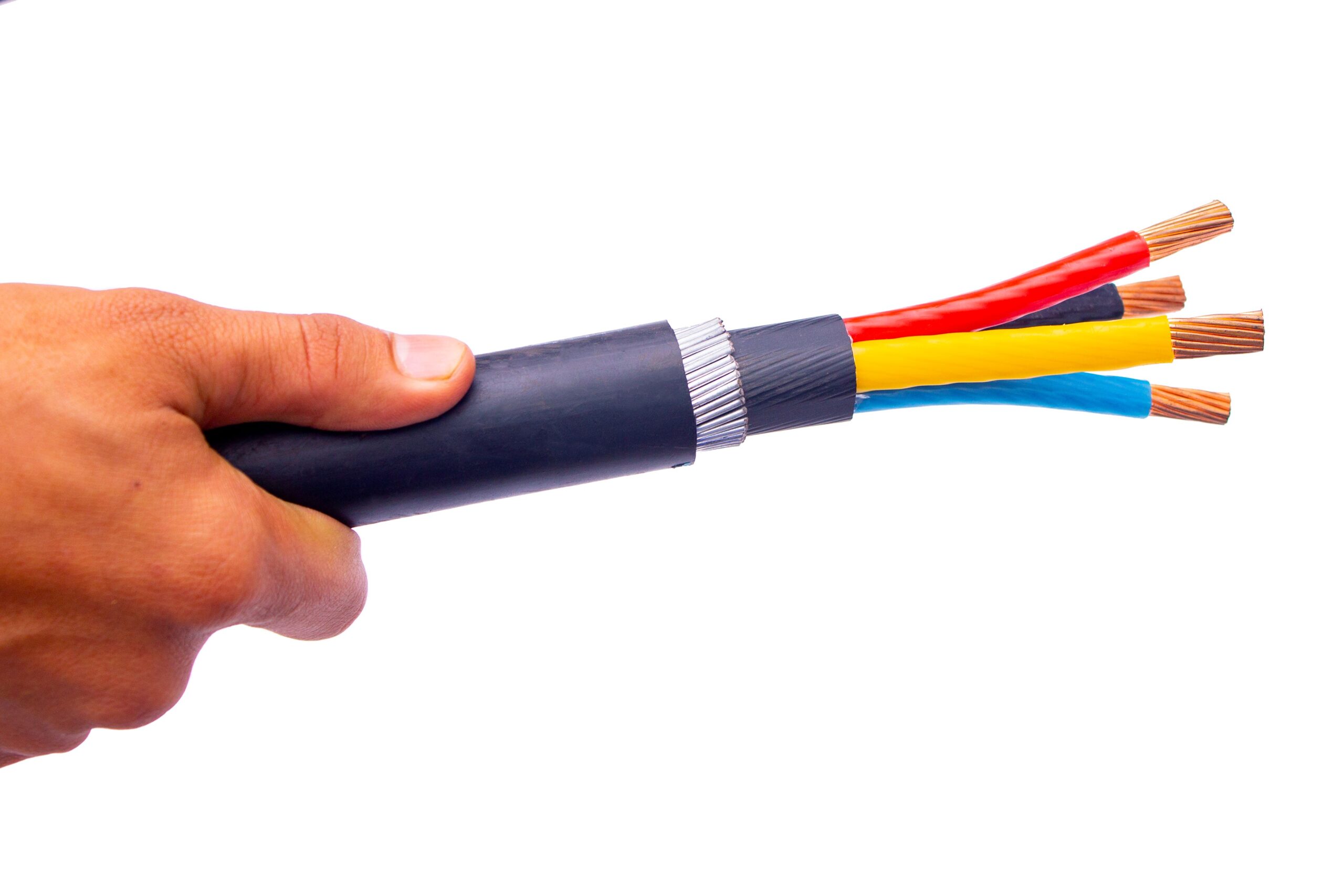

Electrical cables are made from different materials. Copper and aluminum are the most common materials used. Copper is known for its excellent conductivity and flexibility. Aluminum is lighter and often used in high-voltage applications.

Insulation materials also vary. PVC (Polyvinyl Chloride) is a popular choice due to its durability and resistance to chemicals. Rubber is used for flexible cables and provides good heat resistance.

| Material | Properties |

|---|---|

| Copper | Excellent conductivity, flexibility |

| Aluminum | Lighter, used in high-voltage applications |

| PVC | Durable, chemical-resistant |

| Rubber | Heat-resistant, flexible |

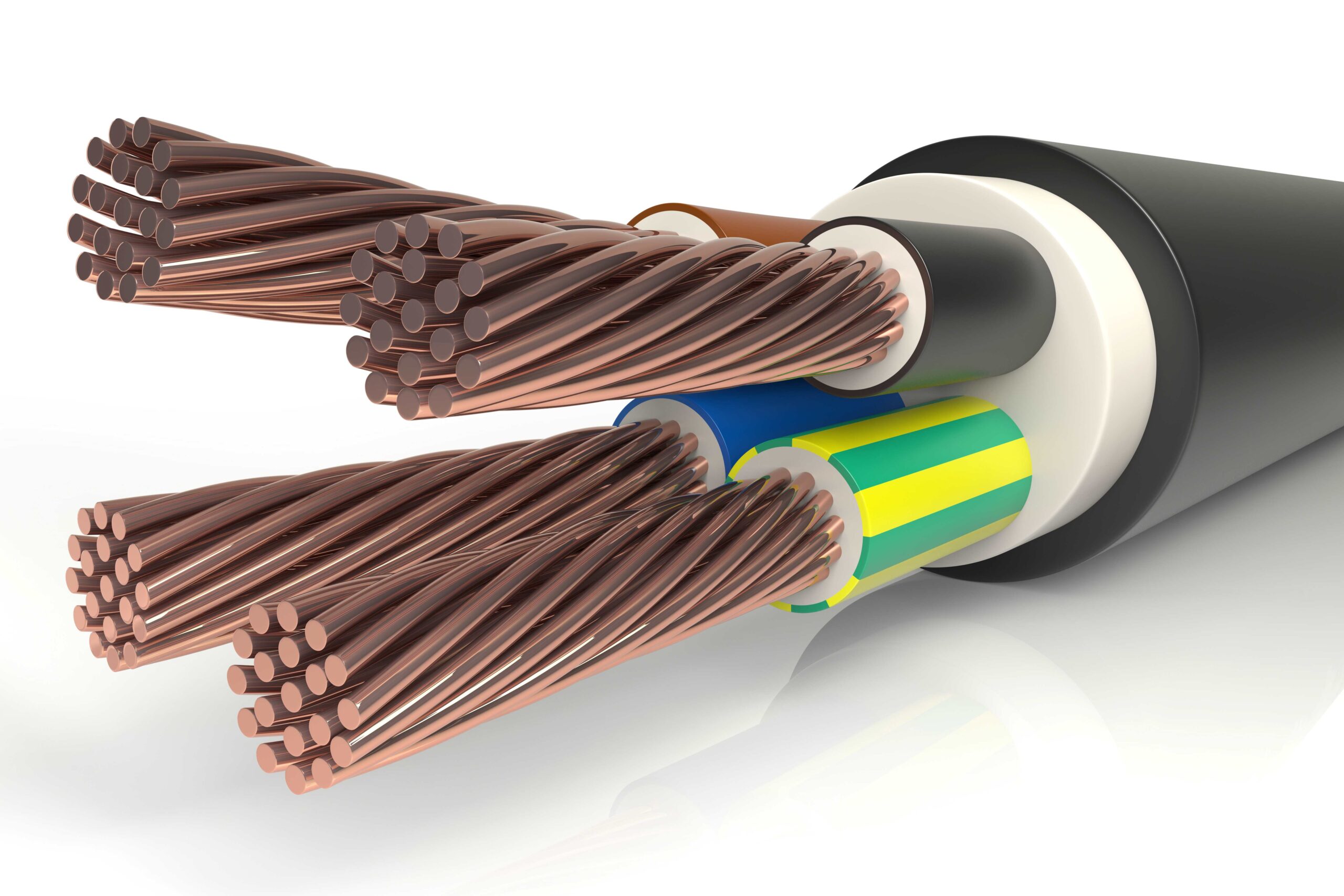

Electrical cables are classified based on their usage. Here are some common types:

- Power Cables: Used for transmitting electrical power.

- Control Cables: Used for controlling electrical equipment.

- Communication Cables: Used for data and voice transmission.

- Coaxial Cables: Used for TV and internet connections.

Power cables are designed to handle high currents. They are commonly used in industrial and residential settings. Control cables are used in automation systems to control machinery. Communication cables are vital for data transfer, used in networking and telecommunications. Coaxial cables have a unique structure that minimizes signal loss, making them ideal for TV and internet.

Choosing the right cable type ensures safety and efficiency in electrical systems. Always consider the specific requirements of your application.

Common Materials Used In Electrical Cables

Electrical cables are made from various materials. Each material has unique properties. Understanding these materials helps in choosing the right cable for your needs.

Copper Cables

Copper cables are widely used. They are known for their excellent conductivity. Copper is also very flexible. It can bend without breaking. This makes it ideal for many applications.

Copper cables are also resistant to corrosion. This increases their lifespan. They are often used in homes and industries. Here are some benefits of copper cables:

- High conductivity

- Flexibility

- Corrosion resistance

- Long lifespan

Aluminum Cables

Aluminum cables are another popular choice. They are lighter than copper cables. This makes them easier to handle. Aluminum cables are also cheaper. This helps in reducing costs.

However, aluminum has lower conductivity than copper. It is also less flexible. Despite these drawbacks, aluminum cables are widely used in power distribution. Key benefits of aluminum cables include:

- Lightweight

- Cost-effective

- Easy to handle

Fiber Optic Cables

Fiber optic cables are different. They do not use metal for conductivity. Instead, they use light. This allows for high-speed data transfer. Fiber optic cables are used in telecommunications and internet connections.

They are also resistant to electromagnetic interference. This makes them very reliable. Here are some advantages of fiber optic cables:

- High-speed data transfer

- Resistance to electromagnetic interference

- Reliable performance

Classification Based On Usage

Electrical cables come in various types. Each type has a specific use. Knowing the differences helps in choosing the right cable for the job.

Power Cables

Power cables carry electricity from one point to another. They are used in homes, offices, and factories. These cables can be found in different sizes and materials.

Important features of power cables include:

- High voltage handling

- Durability

- Insulation quality

| Type | Usage |

|---|---|

| Low Voltage | Home wiring |

| Medium Voltage | Industrial applications |

| High Voltage | Power transmission |

Control Cables

Control cables are used to send control signals. These cables are found in automation systems and machinery. They help in controlling various functions.

Key characteristics of control cables:

- Flexibility

- Resistance to interference

- Durable insulation

Control cables ensure that signals are sent without delay. They are essential for the smooth operation of machines.

Communication Cables

Communication cables transmit data. They are used in telecommunication and internet systems. These cables are designed for fast and reliable data transfer.

Main types of communication cables include:

- Coaxial cables

- Fiber optic cables

- Twisted pair cables

Each type has its own benefits. For instance, fiber optic cables offer high-speed data transfer. Twisted pair cables are used in telephone lines.

Factors To Consider When Choosing Electrical Cables

Choosing the right electrical cables is crucial for safety and efficiency. There are several factors to keep in mind to make the best decision. This guide will help you understand the key aspects to consider.

Voltage Rating

The voltage rating of a cable is one of the most important factors. It determines the maximum voltage the cable can handle. Always choose a cable with a voltage rating higher than the system’s operating voltage.

Current-carrying Capacity

Current-carrying capacity is the amount of current a cable can safely carry. This depends on the cable’s size and material. Choosing a cable with inadequate capacity can lead to overheating and fires.

Here is a table to help you understand different capacities:

| Wire Gauge | Current Capacity (Amps) |

|---|---|

| 14 AWG | 15 |

| 12 AWG | 20 |

| 10 AWG | 30 |

Environmental Conditions

Environmental conditions can affect cable performance. Factors such as temperature, moisture, and exposure to chemicals must be considered. For example, cables used outdoors should be resistant to UV rays and water.

Consider the following points:

- Temperature: Choose cables that can withstand the temperature range of the installation area.

- Moisture: Use moisture-resistant cables in wet environments.

- Chemicals: Select cables that can resist any chemicals they may come into contact with.

Installation And Maintenance Of Electrical Cables

Electrical cables are essential for modern life. Proper installation and regular maintenance ensure their efficiency and safety. This guide covers the best practices for installing and maintaining electrical cables.

Proper Installation Techniques

Proper installation is crucial for the safe operation of electrical cables. Follow these steps for a safe and efficient installation:

- Plan the layout: Draw a detailed plan showing where cables will run.

- Choose the right cables: Select cables that match the voltage and current requirements.

- Use appropriate tools: Ensure you have the right tools for cutting and stripping cables.

- Follow safety guidelines: Wear protective gear and turn off power before starting.

Regular Inspection And Testing

Regular inspection and testing keep your electrical system safe. Follow these tips for effective maintenance:

- Inspect cables for signs of wear and tear every six months.

- Test connections to ensure they are secure and free of corrosion.

- Check insulation for cracks or other damage.

- Use a multimeter to test voltage and current levels.

Maintaining your electrical cables ensures their long life and safety. Always follow the recommended guidelines for installation and maintenance.

Common Issues And Troubleshooting

Electrical cables are essential for powering devices. But, they can face problems. Knowing common issues and troubleshooting them helps maintain safety and performance.

Overheating

Overheating is a frequent issue with electrical cables. It can cause damage and fires.

- Cause: Excessive current flowing through the cable.

- Signs: Warm or hot cable, burning smell.

- Solution: Use a cable with the correct current rating. Reduce the load on the cable.

Short Circuits

Short circuits occur when electrical flow takes an unintended path. This can damage devices and cables.

- Cause: Faulty wiring, damaged insulation.

- Signs: Sparks, burning smell, devices not working.

- Solution: Inspect and replace damaged cables. Ensure proper insulation.

Cable Damage

Cable damage is common due to wear and tear. Damaged cables can be hazardous.

- Cause: Physical damage, rodents, aging.

- Signs: Visible cuts, exposed wires, frayed ends.

- Solution: Replace damaged sections. Use cable protectors.

| Issue | Cause | Signs | Solution |

|---|---|---|---|

| Overheating | Excessive current | Warm cable, burning smell | Use correct rating, reduce load |

| Short Circuits | Faulty wiring, damaged insulation | Sparks, burning smell | Inspect and replace cables |

| Cable Damage | Wear and tear, rodents | Visible cuts, exposed wires | Replace sections, use protectors |

Future Trends In Electrical Cables

The world of electrical cables is evolving. Rapid advancements in technology are driving these changes. The future promises smart cables and renewable energy integration. These trends will transform how we use and manage electrical power.

Development Of Smart Cables

Smart cables are the next big thing. These cables come with embedded sensors. They monitor and report on their own health. Imagine a cable that tells you when it needs replacing. This capability can prevent failures and save costs.

Benefits of Smart Cables:

- Real-time monitoring

- Reduced maintenance costs

- Enhanced safety

Smart cables can adapt to changing conditions. They can optimize energy use. This leads to more efficient systems. Smart cables can also integrate with smart grids. This will make energy distribution smarter and more reliable.

Integration Of Renewable Energy Sources

Renewable energy sources are becoming more popular. Solar and wind power are leading the way. Electrical cables must evolve to support these sources. The integration of renewable energy is crucial for a sustainable future.

Key Features for Integration:

- High durability

- Resistance to harsh weather

- Efficient energy transmission

Modern cables can handle the variable nature of renewable energy. They can withstand extreme temperatures and conditions. These cables ensure that power from renewable sources is stable and reliable.

In summary, the future of electrical cables is bright. Smart cables and renewable energy integration are key trends. These innovations will make our power systems safer, more efficient, and sustainable.

Regulations And Standards For Electrical Cables

Electrical cables need strict rules. These rules ensure safety and reliability. Different regions have different standards. These standards guide how cables are made and used.

National Electrical Code (nec)

The National Electrical Code (NEC) is a key standard in the USA. It sets rules for electrical wiring and cables. The NEC is updated every three years. This keeps it current with new technology.

Here are some important points about the NEC:

- Safety: The NEC focuses on preventing electrical hazards.

- Compliance: All electrical installations must follow the NEC.

- Types of Cables: The NEC specifies which cables to use in different situations.

Electricians must know the NEC. This ensures that all work is safe and legal.

International Electrotechnical Commission (iec) Standards

The International Electrotechnical Commission (IEC) sets global standards. These standards cover many electrical products, including cables. The IEC helps ensure compatibility and safety worldwide.

Key aspects of IEC standards include:

- Global Compatibility: IEC standards make sure products work together globally.

- Safety: Like the NEC, safety is a top priority.

- Quality: IEC standards ensure high-quality materials and construction.

Manufacturers follow IEC standards to sell products internationally. This ensures a high level of quality and safety for all users.

| Standard | Region | Focus |

|---|---|---|

| NEC | USA | Safety and compliance in electrical installations |

| IEC | Global | Compatibility, safety, and quality of electrical products |

Credit: en.wikipedia.org

Sustainable Practices In Cable Manufacturing

Sustainability is key in today’s world. Cable manufacturing is no exception. Companies are adopting eco-friendly practices. This shift helps protect our environment. Let’s explore these sustainable practices.

Recycling Initiatives

Recycling is a cornerstone of sustainability. Cable manufacturers are embracing this. They recycle old and unused cables. This reduces waste and saves resources.

Recycling initiatives ensure that valuable materials are reused. Copper and aluminum are prime examples. These metals can be melted and repurposed. This process consumes less energy compared to mining new materials.

Companies also recycle plastic insulation. This plastic can be transformed into new products. This approach minimizes plastic waste in landfills.

Recycling initiatives include:

- Collection programs for old cables

- Recycling centers for cable materials

- Partnerships with recycling companies

Reducing Environmental Impact

Reducing environmental impact is crucial. Cable manufacturers are taking steps to achieve this. They focus on energy efficiency and reducing emissions.

One way is by using renewable energy sources. Solar and wind power are popular options. These sources reduce the carbon footprint.

Another method is using eco-friendly materials. Biodegradable plastics and non-toxic chemicals are becoming standard. These materials break down naturally and don’t harm the environment.

| Practice | Benefit |

|---|---|

| Renewable energy | Lower carbon emissions |

| Eco-friendly materials | Less environmental harm |

| Energy-efficient processes | Reduced energy consumption |

Reducing environmental impact also involves waste management. Companies implement strict waste protocols. They ensure waste is disposed of responsibly. Recycling and reusing waste materials is part of this approach.

Innovations In Cable Technology

The world of electrical cables has seen remarkable advancements. These innovations ensure better performance, safety, and durability. Let’s dive into some of the most exciting developments in cable technology today.

Nanotechnology Applications

Nanotechnology is revolutionizing electrical cables. This technology enhances conductivity and strength. By incorporating nanoparticles, manufacturers can create cables with superior properties.

- Enhanced conductivity

- Increased strength

- Improved durability

Nanotechnology allows for thinner, more efficient cables. This leads to reduced material costs and environmental impact. These cables are also more resistant to wear and tear, extending their lifespan.

Improved Insulation Materials

Insulation materials play a crucial role in cable performance. Recent innovations have led to the development of better insulation options. These new materials offer enhanced safety and efficiency.

| Material | Benefit |

|---|---|

| Cross-linked Polyethylene (XLPE) | High thermal resistance |

| Thermoplastic Elastomers (TPE) | Superior flexibility |

| Silicone Rubber | Excellent heat resistance |

These improved materials provide better protection against electrical faults. They also enhance the cable’s performance in extreme conditions. This makes them ideal for a wide range of applications.

With these advancements, electrical cables are now safer and more efficient than ever. These innovations are paving the way for a more reliable and sustainable future.

Case Studies Of Successful Cable Installations

Understanding how electrical cables are installed successfully can provide valuable insights. This section explores notable case studies. These examples highlight the efficiency and technology behind modern cable installations.

Undersea Power Cables

Undersea power cables are a marvel of engineering. They connect continents and islands, ensuring a constant power supply. One notable example is the North Sea Link. It connects the UK and Norway, spanning 720 kilometers. This project required advanced planning and state-of-the-art technology.

The cable lies on the seabed, facing strong currents and deep waters. Engineers used robust materials to withstand these conditions. The installation process took years and involved several ships. These ships laid the cable in segments, ensuring precise alignment.

Another successful case is the Basslink Project in Australia. This project connects Tasmania to the mainland. It spans 370 kilometers, with 290 kilometers underwater. The cable can handle high voltage, ensuring reliable power transmission. The project also included environmental assessments to protect marine life.

High-voltage Transmission Lines

High-voltage transmission lines are essential for long-distance power distribution. The Pacific DC Intertie is a prime example. It connects Oregon to Los Angeles, covering over 1,300 kilometers. This project uses direct current (DC) for efficient power transfer. The line can carry up to 3,100 megawatts of power.

Another significant project is the Brahmaputra River Crossing in India. Engineers faced the challenge of spanning the wide river. They used tall towers and strong cables to ensure stability. This project improved power supply to the northeastern regions.

The Inga-Kolwezi Line in the Democratic Republic of Congo is also noteworthy. It spans 1,700 kilometers, delivering power from hydroelectric plants. The project faced geographical challenges, including dense forests and mountains. Engineers overcame these obstacles with innovative solutions.

These successful installations showcase the importance of planning and technology. They ensure reliable power supply across vast distances and challenging environments.

Challenges Faced By The Electrical Cable Industry

The electrical cable industry faces many challenges. These issues impact production, costs, and supply. This blog post highlights two major challenges: supply chain disruptions and rising raw material costs.

Supply Chain Disruptions

Supply chain disruptions affect many industries, including electrical cables. Delays in raw materials and components can halt production. This leads to increased lead times for customers.

Natural disasters, geopolitical tensions, and pandemics can cause these disruptions. Companies may struggle to source essential materials. This can result in higher prices and reduced availability.

Transport issues can also disrupt the supply chain. Shipping delays, port congestion, and customs issues can slow down deliveries. This impacts the industry’s ability to meet demand.

Rising Raw Material Costs

Rising raw material costs present another challenge. Essential materials like copper, aluminum, and plastics are becoming more expensive. These materials are vital for manufacturing electrical cables.

| Material | Impact on Cost |

|---|---|

| Copper | High |

| Aluminum | Moderate |

| Plastics | Variable |

Manufacturers must adjust pricing to cover these costs. This can make products more expensive for consumers. Companies may also need to find alternative materials to reduce costs.

Global demand for raw materials continues to rise. This increases competition and drives up prices. The electrical cable industry must navigate these challenges to remain competitive.

The Role Of Electrical Cables In Renewable Energy Systems

Electrical cables are the lifelines of renewable energy systems. They carry power from generation points to where it is needed. Without these cables, renewable energy could not be efficiently delivered. These systems include solar farms and wind turbines. Each has specific needs for cable connections.

Interconnection Of Solar Farms

Solar farms consist of many solar panels. These panels convert sunlight into electricity. The electricity needs to be collected and sent to the power grid. This is where electrical cables play a crucial role. They connect the panels to inverters and transformers.

| Component | Role of Cables |

|---|---|

| Solar Panels | Connect panels to the inverter |

| Inverter | Convert DC to AC |

| Transformer | Step up voltage for grid |

Key points about solar farm cables:

- They must be weather-resistant.

- They should handle high voltage.

- They need to be efficient to reduce power loss.

Wind Turbine Applications

Wind turbines generate electricity from wind. Each turbine has a generator at the top. The electricity must travel down the tower. This is done using strong, durable cables.

Important features of wind turbine cables:

- Flexibility to handle tower movements.

- Durability against harsh weather.

- High efficiency to ensure minimal power loss.

In wind farms, cables connect multiple turbines to a central point. From there, power is sent to the grid.

Advancements In Fire-resistant Cables

Fire-resistant cables are crucial for safety in buildings and industrial sites. Recent advancements in fire-resistant cables offer better protection and reliability. These new cables are designed to withstand extreme conditions and prevent fire spread.

Enhanced Safety Features

Modern fire-resistant cables come with enhanced safety features. These features include improved insulation and heat-resistant materials. The cables are designed to maintain circuit integrity during a fire.

Another key feature is low smoke emission. This reduces the risk of smoke inhalation during a fire. Fire-resistant cables also have halogen-free materials. This ensures that no toxic gases are released when exposed to heat.

Key Safety Features:

- Improved Insulation

- Heat-Resistant Materials

- Low Smoke Emission

- Halogen-Free Construction

Applications In High-risk Environments

Fire-resistant cables are essential in high-risk environments. These include hospitals, airports, and tunnels. The cables are also used in oil and gas industries. They ensure that critical systems remain operational during a fire.

In tunnels, these cables prevent fire spread and ensure emergency lighting works. In hospitals, they keep life-saving equipment running. Fire-resistant cables are also used in power plants and chemical facilities. These places need reliable fire safety.

High-Risk Environments:

- Hospitals

- Airports

- Tunnels

- Oil and Gas Industries

- Power Plants

- Chemical Facilities

The Impact Of Digitalization On Cable Management

Digitalization has changed how we manage electrical cables. Smart technologies make it easier to monitor and maintain these cables. This ensures better performance and safety.

Remote Monitoring Systems

Remote monitoring systems help track cable conditions in real-time. Sensors can detect issues like overheating or wear and tear. This allows for quick action before problems escalate.

Remote systems reduce the need for manual inspections. This saves time and money. It also minimizes the risk of human error.

A table below summarizes the benefits of remote monitoring:

| Benefit | Description |

|---|---|

| Real-time tracking | Monitors cable conditions 24/7 |

| Quick response | Identifies issues immediately |

| Cost-effective | Reduces manual inspection costs |

| Safety | Minimizes risk of accidents |

Data-driven Maintenance

Data-driven maintenance uses data to predict cable issues. It relies on historical data and real-time information. This helps in planning maintenance activities effectively.

Predictive analytics can forecast potential failures. This allows for proactive repairs. It ensures that cables are always in good condition.

Below is an unordered list of data-driven maintenance benefits:

- Prevents unexpected failures

- Extends cable life

- Reduces maintenance costs

- Improves system reliability

Digitalization in cable management offers many advantages. It enhances efficiency and safety. Utilizing remote monitoring and data-driven maintenance can revolutionize how we manage electrical cables.

Cable Testing And Quality Assurance

Ensuring the quality and reliability of electrical cables is crucial. Rigorous testing helps maintain safety and performance standards. Different tests assess various aspects of cable integrity, such as insulation and conductor resistance. These tests ensure that cables perform effectively in their intended applications.

Insulation Resistance Testing

Insulation resistance testing measures the resistance of the cable’s insulating material. This test checks for any breakdowns in the insulation. It ensures the cable can prevent electrical leakage. High insulation resistance means the cable is safe and reliable.

The test involves applying a high voltage to the cable. This voltage checks the resistance of the insulation. Test results are given in megaohms (MΩ). A higher megaohm value indicates better insulation quality.

- Purpose: To check the integrity of the insulation material.

- Method: High voltage application.

- Measurement: Megaohms (MΩ).

Conductor Resistance Testing

Conductor resistance testing measures the resistance of the cable’s conductor. This test ensures the conductor can carry electrical current efficiently. Low conductor resistance means better performance and less energy loss.

In this test, a known current flows through the conductor. The voltage drop across the conductor is measured. The resistance is then calculated using Ohm’s law. The results are displayed in ohms (Ω).

| Test Type | Purpose | Measurement Unit |

|---|---|---|

| Insulation Resistance | Checks insulation integrity | Megaohms (MΩ) |

| Conductor Resistance | Checks conductor efficiency | Ohms (Ω) |

Both tests are essential for quality assurance. They help identify potential issues before cables are used. This ensures the safety and reliability of electrical systems.

Training And Education For Cable Installers

Electrical cables are crucial for any building. Proper installation ensures safety and efficiency. To become skilled, cable installers need proper training and education. This section explores the pathways to becoming a certified cable installer and the importance of continuous learning.

Certification Programs

Certification programs provide a structured way for installers to gain necessary skills. They cover various aspects of electrical cabling, from basic to advanced techniques.

Here are some popular certification programs:

- National Electrical Contractors Association (NECA): Offers comprehensive courses and certifications.

- Electrical Training Alliance (ETA): Provides a wide range of training modules.

- International Association of Electrical Inspectors (IAEI): Focuses on safety and regulations.

Key benefits of certification programs include:

- Structured learning paths

- Industry-recognized credentials

- Hands-on experience

Continuing Professional Development

Continuing Professional Development (CPD) is vital for staying updated in the field. It helps installers keep up with new technologies and methods.

Ways to engage in CPD:

- Attending workshops and seminars

- Participating in online courses

- Reading industry journals

- Joining professional organizations

Benefits of CPD:

| Benefit | Description |

|---|---|

| Up-to-date Knowledge | Stay informed about the latest industry trends. |

| Enhanced Skills | Improve your technical abilities. |

| Professional Growth | Advance in your career and take on new roles. |

Investing in CPD leads to better job performance and more career opportunities.

Global Market Trends In Electrical Cables

The global market for electrical cables is growing fast. Many factors are pushing this growth. Demand from new markets and new technology are key drivers. Let’s dive into these trends.

Demand In Emerging Economies

Emerging economies are seeing a rise in demand for electrical cables. Countries like India, China, and Brazil need more power. This need is due to fast urbanization and industrial growth.

New infrastructure projects in these nations require lots of electrical cables. Construction of new buildings, roads, and power plants all need cables. This boosts the market demand.

| Country | Reason for Demand |

|---|---|

| India | Urbanization and smart cities |

| China | Industrial growth and 5G rollout |

| Brazil | Power grid expansions |

Technological Advancements Driving Growth

New technologies are making electrical cables better. Smart cables can now monitor their own performance. This helps in maintaining a reliable power supply.

Environment-friendly cables are also gaining popularity. These cables are made from recyclable materials. They are safer and reduce pollution.

- Smart cables monitor performance

- Environment-friendly cables reduce pollution

- High-speed data cables support faster internet

High-speed data cables are another key trend. They support faster internet and data transfer. This is crucial for modern communication needs.

Frequently Asked Questions

What Are The Three Types Of Electrical Wires?

The three types of electrical wires are: 1. **Live wire (Hot wire)**: Carries current to the appliance. 2. **Neutral wire**: Returns current to the source. 3. **Ground wire**: Provides a path for electrical faults, ensuring safety.

What Are The Three Basic Types Of Cables?

The three basic types of cables are coaxial, twisted pair, and fiber optic. Coaxial cables transmit television signals. Twisted pair cables connect telephones and computers. Fiber optic cables offer high-speed internet and data transmission.

What Cable Is Used For Electricity?

Copper or aluminum cables are commonly used for electricity. These materials conduct electricity efficiently and are durable.

What Cables Do Electricians Use?

Electricians commonly use NM cable, THHN/THWN wire, MC cable, and UF cable. Each type serves specific electrical needs.

Conclusion

Choosing the right electrical cables is crucial for safety and efficiency. Always consider your specific needs and consult professionals. Proper installation and maintenance extend the lifespan of cables. Stay informed and prioritize quality to ensure reliable electrical systems. With the right cables, you can prevent issues and ensure smooth operations.