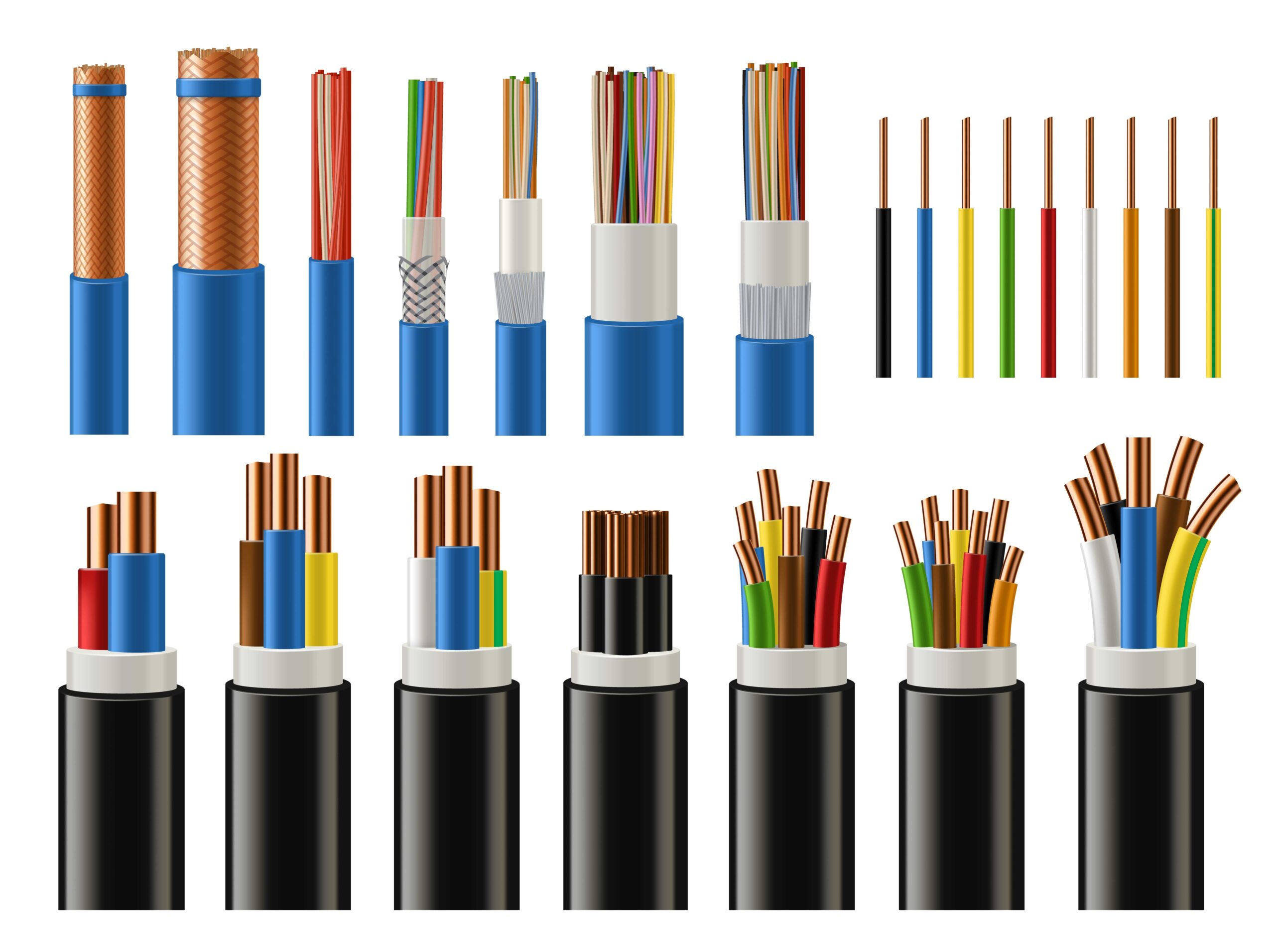

There are several types of electrical wires, including single-conductor, multi-conductor, and coaxial cables. Each type serves specific electrical needs.

Electrical wires are essential in modern infrastructure, powering homes, offices, and industries. Single-conductor wires, often made of copper or aluminum, are widely used for general electrical applications. Multi-conductor cables contain multiple wires within a single sheath, ideal for complex electrical systems.

Coaxial cables, known for their insulated design, are perfect for transmitting television and internet signals. Each type has unique properties, such as insulation, flexibility, and conductivity, making them suitable for different environments and uses. Understanding these types helps in choosing the right wire for any electrical project, ensuring safety and efficiency.

Conductors

Electrical wires are essential for carrying electric current. The wire’s core, known as the conductor, plays a vital role in its efficiency. Conductors come in various materials, but the most common types are copper and aluminum. Each type has its own set of benefits and uses.

Copper Wires

Copper wires are the most popular choice for electrical wiring. They offer excellent conductivity, which means they can carry more current with less resistance. This makes them ideal for both residential and commercial applications.

Here are some key benefits of copper wires:

- High conductivity

- Durability and long lifespan

- Resistance to corrosion

- Flexibility for easy installation

Copper wires are commonly used in household wiring, electrical panels, and high-performance electronics. Their superior conductivity ensures efficient energy transfer, making them a reliable choice for most electrical systems.

Aluminum Wires

Aluminum wires are another option for electrical wiring. They are lighter than copper wires, which makes them easier to handle and install. Although they have lower conductivity compared to copper, they are still effective for many applications.

Key benefits of aluminum wires include:

- Lightweight and easy to work with

- Cost-effective

- Good conductivity for specific uses

Aluminum wires are often used in power distribution networks, overhead power lines, and certain types of appliances. They are especially useful in situations where weight and cost are major considerations.

Below is a comparison table of copper and aluminum wires:

| Feature | Copper Wires | Aluminum Wires |

|---|---|---|

| Conductivity | High | Moderate |

| Weight | Heavier | Lighter |

| Cost | Higher | Lower |

| Durability | High | Moderate |

| Resistance to Corrosion | High | Moderate |

Choosing the right type of conductor depends on the specific needs of your electrical project. Both copper and aluminum wires have their own advantages, making them suitable for different applications.

Insulators

Electrical wires use insulators to protect and guide the flow of electricity. Insulators are materials that do not conduct electricity. They keep the wires safe from damage and prevent electrical shocks. Two common types of insulators are PVC insulated wires and rubber insulated wires.

Pvc Insulated Wires

PVC (Polyvinyl Chloride) insulated wires are very popular. They are used in many electrical systems. PVC is a durable and flexible material. It is resistant to water and chemicals. These features make it ideal for household and industrial wiring.

Benefits of PVC insulated wires include:

- Durability: PVC lasts long and withstands wear and tear.

- Flexibility: Easy to bend and install in various settings.

- Safety: Resistant to fire, water, and chemicals.

- Cost-effective: Affordable and widely available.

Common applications of PVC insulated wires:

- Home wiring

- Building construction

- Industrial equipment

Rubber Insulated Wires

Rubber insulated wires are known for their flexibility and toughness. Rubber can handle high temperatures and harsh conditions. This makes it suitable for heavy-duty applications.

Benefits of rubber insulated wires include:

- High heat resistance: Can withstand high temperatures without melting.

- Flexibility: Easy to bend and twist, perfect for complex installations.

- Durability: Resistant to physical damage and abrasion.

- Safety: Provides excellent insulation, reducing the risk of electrical shocks.

Common applications of rubber insulated wires:

- Automotive wiring

- Heavy machinery

- Outdoor equipment

Specialized Wires

Specialized wires are crucial in various applications where standard electrical wires cannot perform effectively. These wires are designed to meet specific requirements and ensure safety, efficiency, and reliability in their respective fields.

Fiber Optic Cables

Fiber optic cables use light to transmit data at high speeds. They are ideal for internet and telecommunications. These cables consist of glass or plastic fibers. Each fiber carries data as light pulses.

Fiber optic cables offer several advantages:

- High-speed data transfer: Faster than traditional copper wires.

- Greater bandwidth: Handle more data simultaneously.

- Less signal loss: Maintain signal quality over long distances.

- Immunity to electromagnetic interference: Unaffected by electrical noise.

Applications of fiber optic cables include:

- Internet services

- Telecommunications

- Medical imaging

- Military communications

Fire-resistant Wires

Fire-resistant wires are designed to withstand high temperatures and prevent the spread of fire. They are essential in ensuring safety in buildings and critical infrastructure.

Key features of fire-resistant wires include:

- High-temperature resistance: Operate safely in extreme heat.

- Non-toxic insulation: Prevents release of harmful fumes during a fire.

- Enhanced durability: Resists wear and tear under harsh conditions.

Common uses of fire-resistant wires:

- Emergency power systems

- Fire alarm systems

- Smoke detectors

- Control circuits in industrial settings

Fire-resistant wires are vital for maintaining safety and functionality during emergencies. They help protect lives and property by minimizing fire hazards.

Credit: www.angi.com

Usage

Electrical wires are essential in both homes and industries. Different types serve various purposes. Knowing their usage helps in selecting the right wire for your needs.

Residential Applications

In homes, electrical wires are used for many purposes. Romex is the most common type. It is used for lighting and outlets. THHN wire is often found in conduit systems. It is used for high-temperature areas. UF-B wire is used for underground wiring. It is great for outdoor lighting and sheds.

Table of common residential wires:

| Wire Type | Usage |

|---|---|

| Romex | Lighting and outlets |

| THHN | Conduit systems, high-temperature areas |

| UF-B | Underground wiring, outdoor lighting |

Industrial Applications

In industries, wires need to handle more power. MC Cable is often used. It is strong and durable. XHHW wire is used in wet locations. It has a thick insulation. Tray Cable is used in cable trays. It is flexible and easy to install.

Table of common industrial wires:

| Wire Type | Usage |

|---|---|

| MC Cable | General industrial wiring |

| XHHW | Wet locations |

| Tray Cable | Cable trays, flexible installations |

Safety Considerations

When dealing with electrical wires, safety is the top priority. Incorrect handling can lead to serious hazards. This guide covers key safety considerations, focusing on proper installation practices and regular maintenance tips.

Proper Installation Practices

Proper installation ensures your electrical system functions safely. Always use wires rated for the specific voltage and current. Never mix different wire types in the same circuit.

Here are some essential installation practices:

- Use insulated wires to prevent electric shocks.

- Follow the color codes for wiring: black for hot, white for neutral, green for ground.

- Ensure all connections are secure and tight.

- Keep wires away from water and heat sources.

- Use cable clamps to secure wires and prevent movement.

Regular Maintenance Tips

Regular maintenance keeps your electrical system safe and functional. Inspect wires periodically to check for damage.

Here are some maintenance tips:

- Check for frayed or exposed wires and replace them immediately.

- Inspect connections and tighten any loose screws.

- Ensure there is no corrosion or rust on terminals.

- Use a voltage tester to check if wires are live before touching them.

- Replace any damaged insulation on wires.

Following these practices ensures a safe and efficient electrical system. Always prioritize safety when dealing with electrical wires.

Environmental Impact

The environmental impact of electrical wires is a critical consideration. Understanding how different types of electrical wires affect the environment helps us make eco-friendly choices. This section will explore the environmental impact of electrical wires by examining recycling options and green alternatives.

Recycling Options

Recycling electrical wires is an effective way to reduce waste. It also conserves natural resources. Here are some recycling options:

- Copper Wires: Copper is highly recyclable. It retains its properties even after recycling. Many recycling centers accept copper wires.

- Aluminum Wires: Aluminum can also be recycled. Recycling aluminum saves a significant amount of energy.

- Plastic Insulation: The plastic insulation on wires is recyclable. Specialized facilities handle this recycling process.

Recycling helps keep harmful materials out of landfills. It also reduces the demand for new raw materials.

Green Alternatives

Green alternatives to traditional electrical wires can further minimize environmental impact. These alternatives focus on sustainable materials and energy efficiency. Consider these options:

| Type | Benefits |

|---|---|

| Biodegradable Insulation: | Uses natural materials. Reduces plastic waste. |

| Recycled Metal Wires: | Made from recycled metals. Lowers energy consumption during production. |

| Low-Emission Production: | Manufactured with eco-friendly processes. Reduces greenhouse gas emissions. |

Choosing green alternatives supports a healthier planet. It also promotes a sustainable future.

Future Trends

The world of electrical wires is evolving rapidly. New technologies are changing the way we think about wiring. Future trends are focused on making systems smarter and more efficient. Let’s dive into some exciting developments.

Smart Wires With Iot Integration

Smart wires are becoming a reality. These wires have built-in sensors and Internet of Things (IoT) integration. They can monitor their own performance and report issues in real-time.

Imagine wires that can detect faults and notify you immediately. This can prevent electrical failures and improve safety. Smart wires can also optimize energy usage by communicating with other smart devices.

| Feature | Benefit |

|---|---|

| Built-in Sensors | Real-time Monitoring |

| IoT Integration | Smart Device Communication |

| Fault Detection | Improved Safety |

| Energy Optimization | Efficient Power Usage |

Increased Efficiency In Power Transmission

Efficiency in power transmission is crucial. New wire technologies aim to reduce energy loss during transmission. This means more power reaches its destination.

High-temperature superconductors are one such innovation. They can carry more current with less resistance. This results in lower energy waste and cost savings.

- High-temperature superconductors: Carry more current with less resistance.

- Advanced materials: Use of new materials reduces energy loss.

- Enhanced insulation: Better insulation minimizes leakage.

Better insulation also plays a key role. New materials are being developed to enhance insulation and minimize leakage. This ensures maximum efficiency in power transmission.

Frequently Asked Questions

What Are The Three Types Of Electrical Wires?

The three types of electrical wires are: 1. **Live (Hot) Wire:** Carries current from the power source to the device. 2. **Neutral Wire:** Returns current from the device to the power source. 3. **Ground Wire:** Provides a safe path for electricity in case of a fault.

What Are The 4 Types Of Wires In Use?

The four types of wires in use are copper, aluminum, fiber optic, and coaxial. Copper wires are common in electrical systems. Aluminum wires are lightweight and cost-effective. Fiber optic wires offer high-speed data transmission. Coaxial cables are used for cable television and internet.

What Type Of Electrical Wiring Is Used In Homes?

Homes typically use Romex (NM) cable for electrical wiring. It consists of three wires: hot, neutral, and ground.

What Are The 4 Electrical Wires?

The four electrical wires are live (black or red), neutral (white), ground (green or bare), and hot (black or red).

Conclusion

Understanding the different types of electrical wires is crucial for safety and efficiency. Whether you’re a DIY enthusiast or a professional, choosing the right wire ensures reliable electrical systems. Always consult a qualified electrician for complex projects. Stay informed and make smart choices to keep your electrical systems safe and functional.